You agree to Sulong Terms and Privacy Policy.

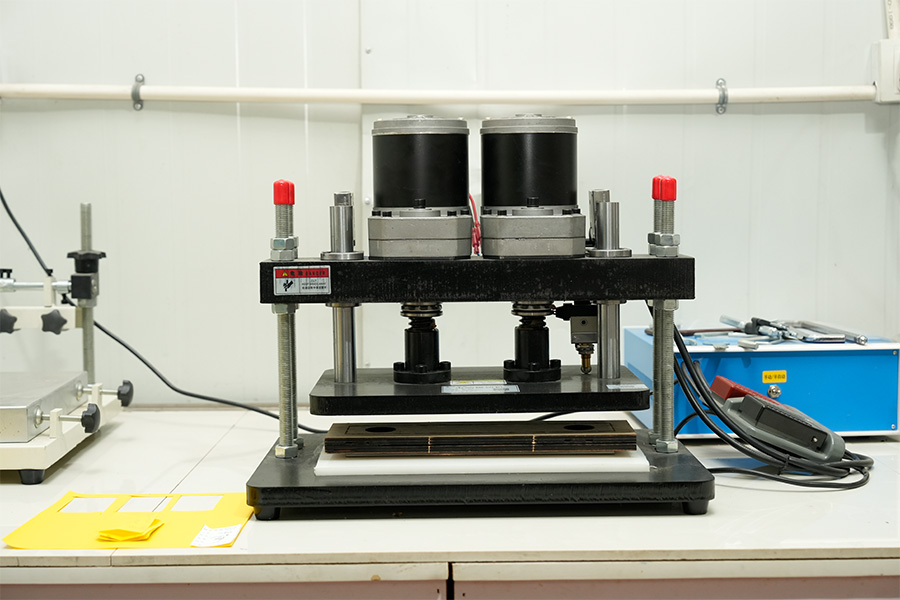

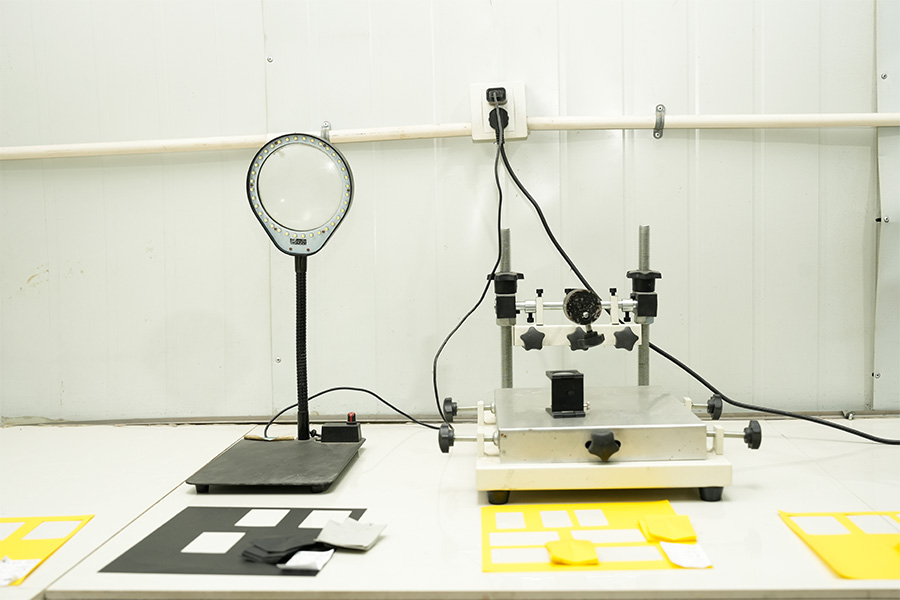

Our Testing Equipment

Sulong's R&D center and laboratories are equipped with state-of-the-art testing equipment. Tests for tear strength, breaking strength, flame retardancy, chemical resistance, water column resistance, color fastness, aging, etc. are all performed in-house. We are proud to have state-of-the-art testing equipment for all our technical textile collections as well.

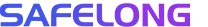

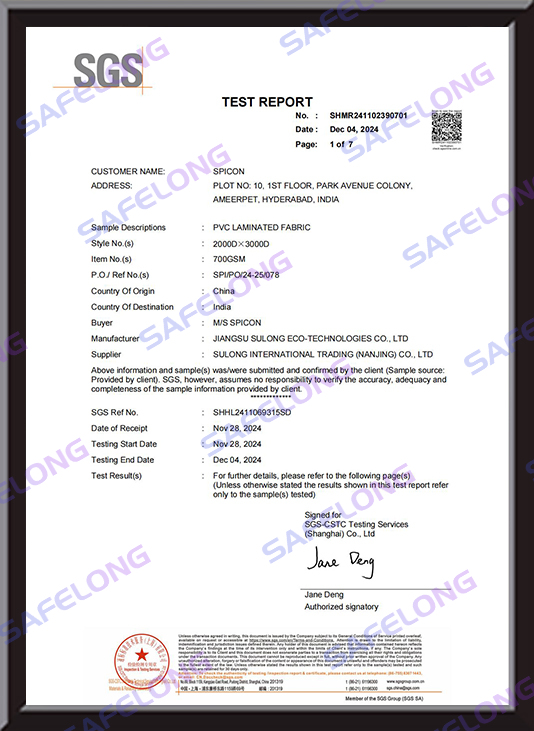

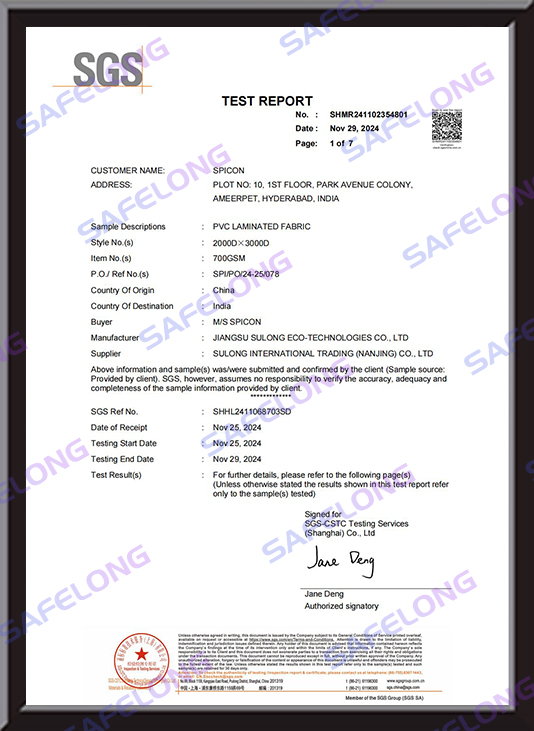

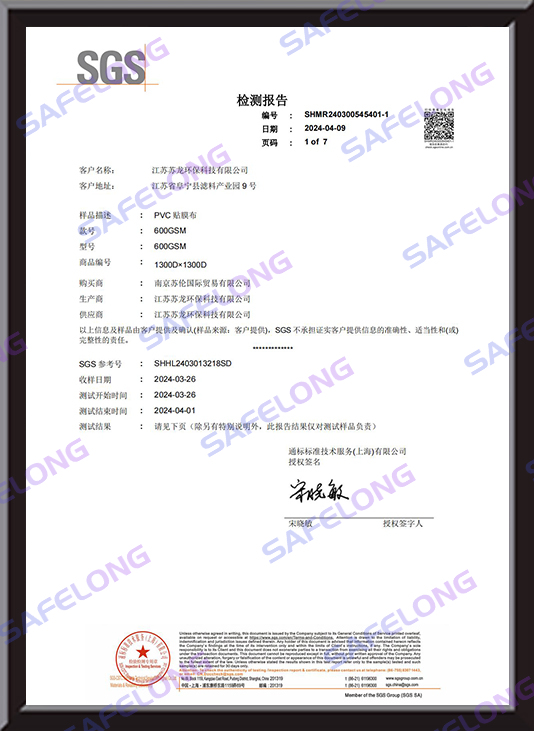

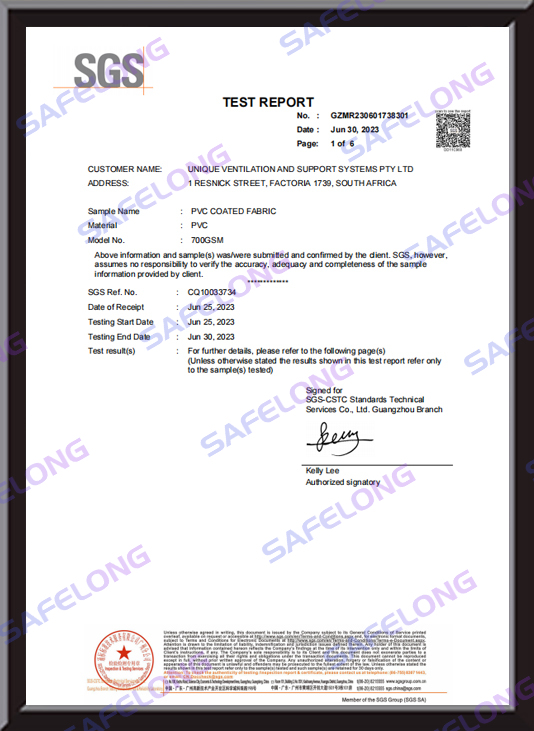

Test Report Display

We will continue to pursue excellence with high standards and rigorous attitude, and provide customers with high-quality products and services.

View MoreWaterproof Test

Spray test: We use spray test to evaluate the water resistance of products or materials. This test usually sprays water onto the product under controlled conditions to evaluate its resistance to moisture.

Hydrostatic pressure test: This standard specifies the hydrostatic pressure method to determine the water penetration resistance of fabrics.

Hydrostatic pressure test: This standard specifies the hydrostatic pressure method to determine the water penetration resistance of fabrics.

Determination of flex cracking resistance

Based on DIN53354 Standard or ASTM Standard (or other types of national standard), sampling fabric would undergo a grab test to meet customer requirement by in-house tensile strength tester.

Inspectors set up related data and supervise the whole process step by step to get the result precisely.

Inspectors set up related data and supervise the whole process step by step to get the result precisely.

Flame Retardant Test

For underground ventilation ducting, the flame-resistant properties need to be fully understood so that the flexible hose can be used safely in the engineered operation work.

For delivering fabric product that meets NFPA 701 Standard, a Sulong expert performs the test in the flame chamber to measure the flammability of a fabric when it is exposed to specific sources of ignition.

For delivering fabric product that meets NFPA 701 Standard, a Sulong expert performs the test in the flame chamber to measure the flammability of a fabric when it is exposed to specific sources of ignition.

Low-Temperature Bend Test

Fabrics coated with PVC are used in underground ventilation requiring low-temperature flexing.

Referred to the GB, ASTM and Din Standards, the test method evaluates the ability of fabric sample in the low-temperature chamber to withstand a selected bend at an established low temperature.

Referred to the GB, ASTM and Din Standards, the test method evaluates the ability of fabric sample in the low-temperature chamber to withstand a selected bend at an established low temperature.

Finished Duct Inspection

After the ventilation ducts and fabric rolls are completed, the inspector will conduct random inspections on the appearance, hot welding seam, suspension seam, end connection coupling and tightness and other aspects. If everything meets the SULOGN acceptance standards, the cargoes can be folded and packed into the warehouse and awaiting delivery instructions. If not, we will increase the rate of spot checks. when the failure rate exceeds 5%, we will reschedule the batch production.

To further enhance our customers' confidence in the quality of our products,we also can accept the third part inspection!

To further enhance our customers' confidence in the quality of our products,we also can accept the third part inspection!

Lab Environment

Need Help to Complete Your Project?

English

English Español

Español русский

русский