You agree to Sulong Terms and Privacy Policy.

-

Fabrics for the Automotive Industry

The materials produced by tarpaulin manufacturers can be applied in various areas of the automotive industry, including car seat covers, roof covers, door interiors, and trunk linings. These materials are typically required to possess properties such as wear resistance, tear resistance, waterproofing, and flame retardancy.

-

Flysheet

The materials produced by tarpaulin manufacturers are essential components of tents, including tent fabric, support poles, and zippers. These materials must exhibit excellent tear resistance, waterproofing, UV protection, and flame retardancy to ensure the durability and safety of the tents.

-

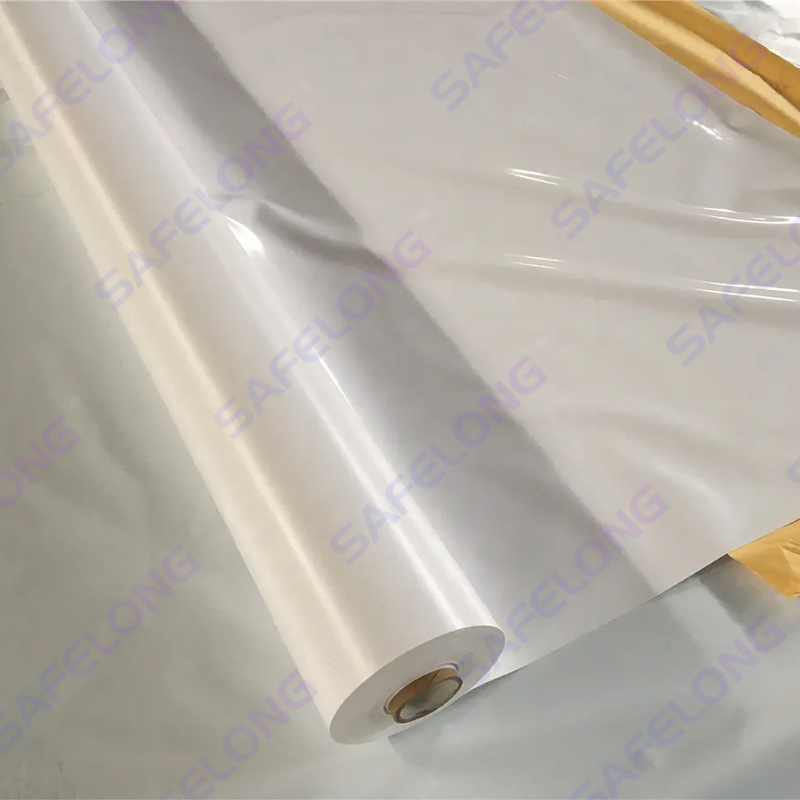

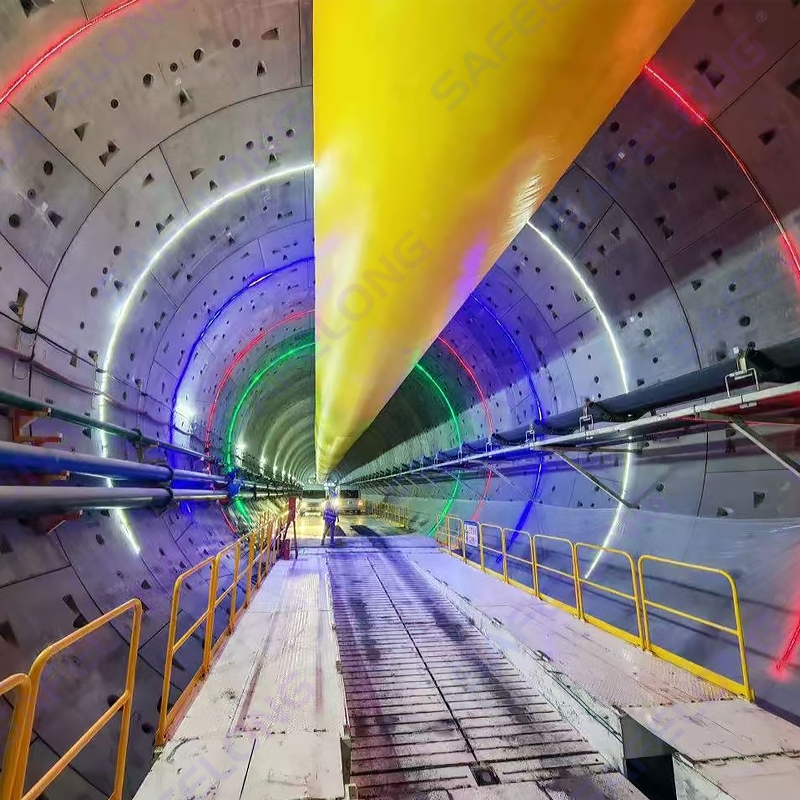

Ventilation Duct

The materials produced by tarpaulin manufacturers can be used to produce ventilation ducts, such as air conditioning ducts and smoke exhaust ducts. These materials need to offer good flexibility, high-temperature resistance, tear resistance, and dust resistance to ensure reliable duct performance.

-

Membrane Construction

Tarpaulin materials are also widely used in membrane structure buildings, such as stadiums, exhibition centers, and airport terminals. These materials must have excellent tear resistance, waterproofing, UV protection, and flame retardancy to guarantee the durability and safety of membrane structures.

-

Inflatable Boat Materials

Tarpaulin materials are suitable for manufacturing inflatable boats, including hulls, bottoms, and cabins. These materials must feature high tear resistance, waterproofing, and abrasion resistance to ensure the safety and longevity of inflatable boats.

-

Tarpaulin

Tarpaulin materials are widely used in outdoor applications such as sunshades, rain covers, and dust protection. These materials should provide strong tear resistance, waterproofing, UV protection, and flame retardancy to ensure their durability and safety.

-

Luggage Fabric

Tarpaulin materials are also ideal for making bags such as backpacks, handbags, and suitcases. They need to have strong tear resistance, abrasion resistance, and waterproofing to ensure the durability and practicality of the luggage.

-

Waterproof Cloth

Tarpaulin materials can be used to manufacture water bags, including outdoor hydration packs and firefighting water tanks. These materials must offer excellent tear resistance, waterproofing, and wear resistance to ensure their durability and safety.

-

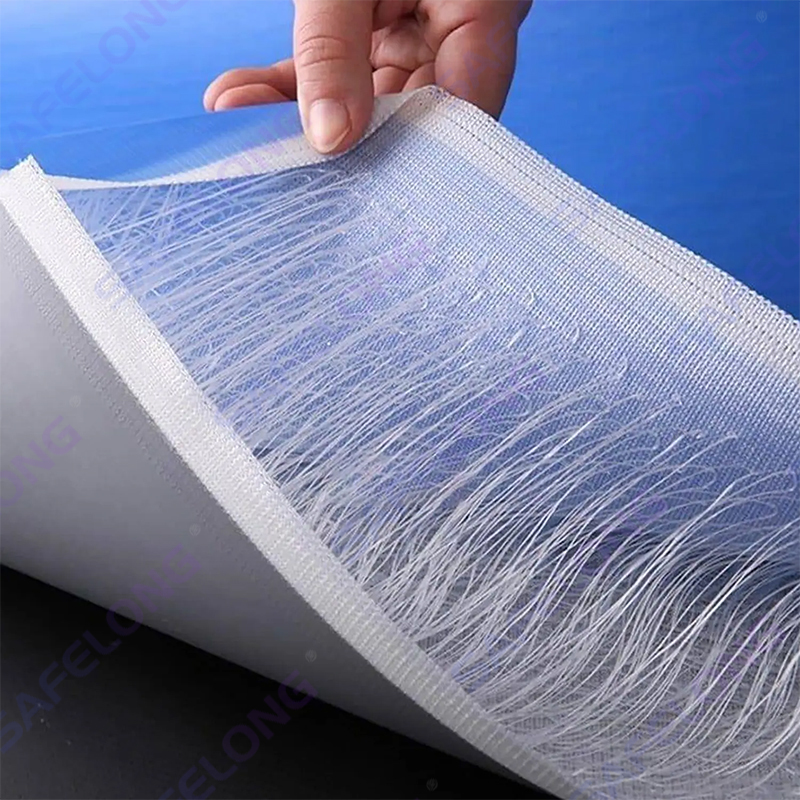

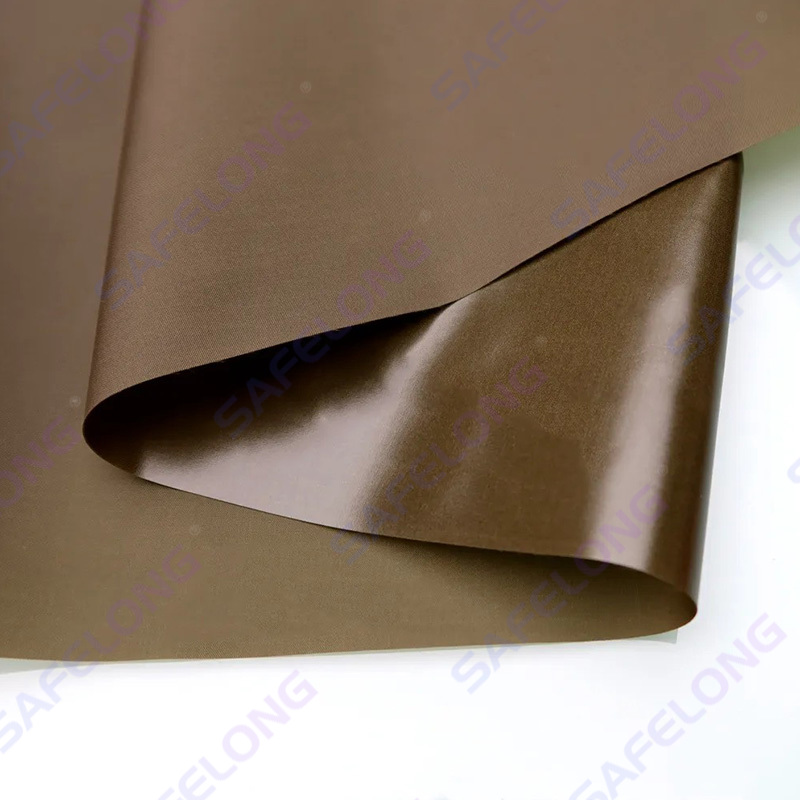

TPU Waterproof Fabric

TPU (thermoplastic polyurethane) waterproof fabric is a high-performance material known for its waterproofing, abrasion resistance, tear resistance, and flame retardancy. It is widely used in outdoor sports, military, and medical fields, such as in rain jackets, waterproof footwear, and medical protective gear.

English

English Español

Español русский

русский