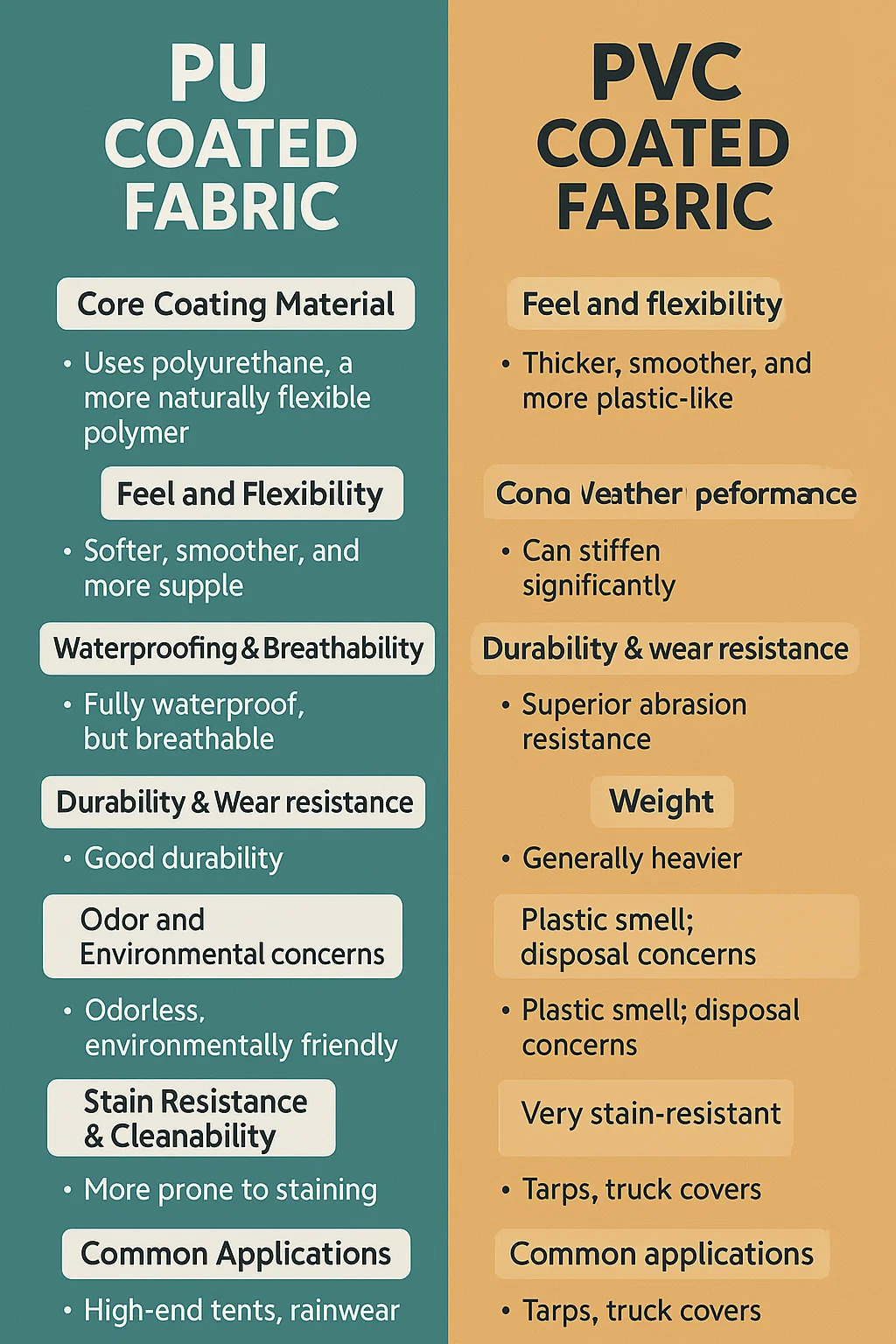

Here's a breakdown of the key differences between PU coated fabric and PVC coated fabric, based on practical characteristics and applications:

Content

●Core Coating Material:

PVC: Uses Polyvinyl Chloride, a rigid plastic softened with additives (plasticizers). plastic softened with additives (plasticizers).

PU: Uses Polyurethane, a more naturally flexible polymer without needing heavy plasticizers.

●Feel and Flexibility:

PVC: Feels thicker, stiffer, and Feels thicker, stiffer, and more rubbery or plastic-like. more rubbery or plastic-like. Remains flexible but has inherent rigidity.

PU: Softer, smoother, and more supple. Drapes supple. Drapes like fabric and feels less synthetic.

●Cold Weather Performance:

PVC: Can stiffen significantly in freezing temperatures, becoming brittle and harder to handle.

PU: Maintains excellent flexibility even in extreme cold, resisting cracking or hardening.

●Waterproofing & Breathability:

PVC: Completely waterproof barrier; not Completely waterproof barrier; not breathable. Traps moisture/vapor underneath.

PU: Fully waterproof, but can be engineered for varying degrees of moisture vapor breathability (letting sweat vapor escape).

●Durability & Wear Resistance:

PVC: Superior resistance to abrasion, punctures, and tearing. Better for heavy abrasion or sharp edges.

PU: Good durability, but generally less abrasion-resistant than PVC. Prone to scuffing and surface wear over time.

●Environmental Resistance:

PVC: Excellent UV resistance when properly stabilized. Resists mold, mildew, and many chemicals. Plasticizers can migrate or leach over time.

PU: Good UV resistance, but long-term exposure can cause hydrolysis (breakdown from moisture/heat) or surface tackiness. Resists mold/mildew.

●Weight:

PVC: Generally heavier for comparable strength/thickness due to denser material.

PU: Typically lighter weight while maintaining strength and waterproofness.

●Odor and Environmental Concerns:

PVC: Often has a noticeable plastic smell, especially when new or hot. Recycling is complex; disposal concerns exist.

PU: Usually odorless. Seen as more environmentally friendly than PVC, though not without impacts.

●Stain Resistance & Cleanability:

PVC: Very stain-resistant; wipes clean easily. Tolerant of mild cleaners.

PU: More prone to staining (especially oil-based) and can be harder to clean. Sensitive to solvents.

●Common Applications:

PVC: Heavy-duty tarps, truck covers, inflatable boats, industrial curtains, pond liners, signage needing extreme durability.

PU: High-end tents, lightweight rainwear, technical outerwear, luggage, comfortable upholstery, medical applications, items needing breathability.

●Cost:

PVC: Generally the more cost-effective option for heavy-duty waterproofing.

PU: Typically more expensive, reflecting its performance in flexibility, feel, and breathability.

English

English Español

Español русский

русский