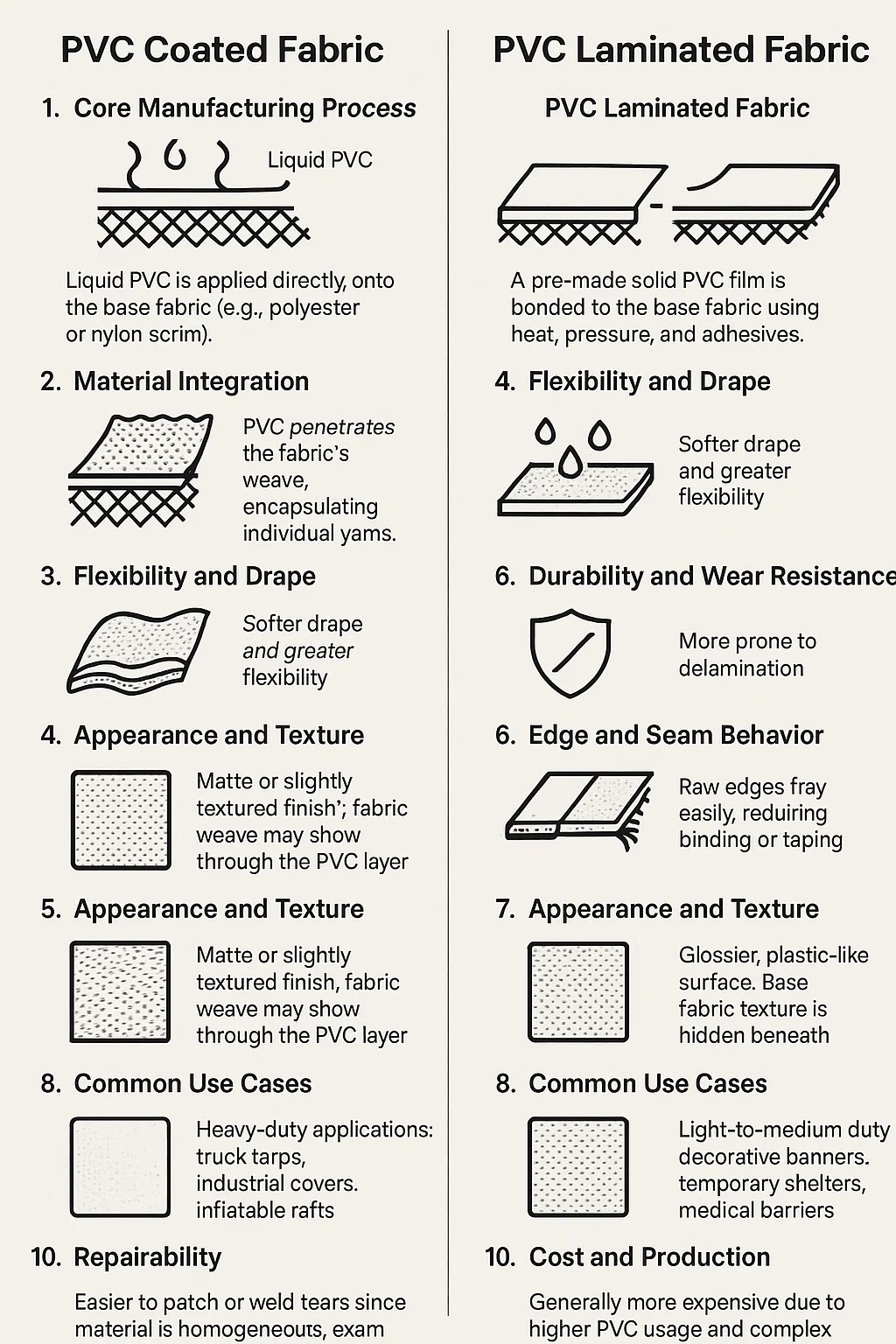

Here's the difference between PVC coated fabric and PVC laminated fabric explained point by point:

1. Core Manufacturing Process

PVC Coated Fabric: Liquid PVC is applied directly onto the base fabric (e.g., polyester or nylon scrim). The fabric passes through a bath of molten PVC or paste, saturating the weave before curing.

PVC Laminated Fabric: A pre-made solid PVC film is bonded to the base fabric using heat, pressure, and adhesives. The fabric and film remain distinct layers fused together.

2. Material Integration

Coated: PVC penetrates the fabric's weave, encapsulating individual yarns. The PVC and fabric merges. The PVC and fabric merge into a single cohesive unit.

Laminated: PVC film sits atop the fabric surface without deep penetration. The layers bond at the interface but retain separate identities.

3. Flexibility and Drape

Coated: Stiffer and more rigid due to PVC saturating the fibers. Resists folding creases but may feel heavier.

Laminated: Softer drape and greater flexibility. The fabric moves more freely since PVC only covers the surface.

4. Waterproofing Effectiveness

Coated: Superior waterproofing as PVC seals the fabric's pores internally. Resists water ingress even at cut edges.

Laminated: Relies on the film's integrity. If the bond fails or edges fray, water may seep between layers or through exposed fabric.

5. Durability and Wear Resistance

Coated: Highly resistant to abrasion, tearing, and punctures. PVC reinforcement extends the fabric's lifespan significantly.

Laminated: More prone to delamination (peeling) under stress. Surface scratches or impacts may compromise the film layer.

6. Edge and Seam Behavior

Coated: Cut edges resist fraying; seams hold well due to integrated PVC. Heat welding creates strong joins.

Laminated: Raw edges fray easily, requiring binding or taping. Seams risk separation if adhesive fails.

7. Appearance and Texture

Coated: Matte or slightly textured finish; fabric weave may show through the PVC layer subtly.

Laminated: Glossier, plastic-like surface. Base fabric texture is hidden beneath the smooth film.

8. Common Use Cases

Coated: Heavy-duty applications: truck tarps, industrial covers, inflatable rafts, protective gear, and military equipment.

Laminated: Light-to-medium duty: decorative banners, temporary shelters, medical barriers, furniture covers, and consumer goods.

9. Repairability

Coated: Easier to patch or weld tears since material is homogeneous.

Laminated: Repairs are challenging; peeling film often requires full edge resealing.

10. Cost and Production

Coated: Generally more expensive due to higher PVC usage and complex curing processes.

Laminated: Lower-cost option; faster production using pre-made films and adhesives.

English

English Español

Español русский

русский