Content

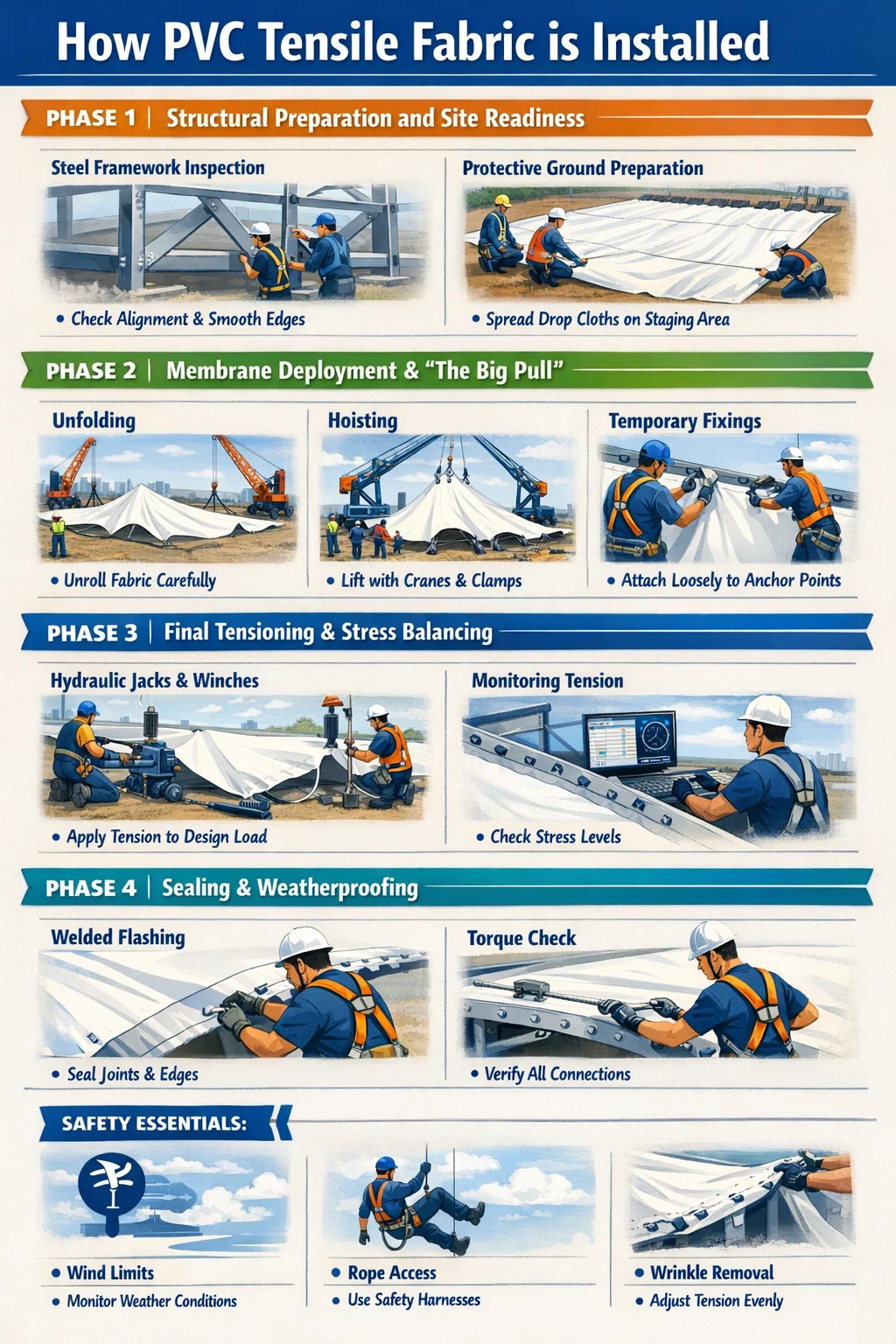

- 1 The Direct Answer: How PVC Tensile Fabric is Installed

- 2 Phase 1: Structural Preparation and Site Readiness

- 3 Phase 2: Membrane Deployment and "The Big Pull"

- 4 Phase 3: Final Tensioning and Stress Balancing

- 5 Phase 4: Sealing, Weatherproofing, and Finishing

- 6 Essential Safety Factors During Installation

The Direct Answer: How PVC Tensile Fabric is Installed

Installing PVC tensile fabric is a precision-engineered process that transforms a flexible membrane into a rigid, structural roof. Unlike traditional roofing, the installation relies on engineered tension rather than mass. The process begins with the erection of a primary steel or timber support structure, followed by the careful unrolling of the fabric, attachment to perimeter fixings, and a systematic "tensioning" phase where the material is pulled to its calculated design stress to ensure wind and snow load resistance.

Phase 1: Structural Preparation and Site Readiness

Before the PVC tensile fabric even arrives at the site, the supporting skeleton must be perfectly aligned. Because tensile structures distribute loads across the entire surface of the membrane, even a minor misalignment in the steel columns can lead to wrinkles or structural failure.

Steel Framework Inspection

The installation team must verify that all connection points, such as gusset plates and pin joints, are positioned exactly as specified in the 3D model. Surface smoothness is critical; any burrs or sharp edges on the steel must be sanded down to prevent tearing the membrane during the pull.

Protective Ground Preparation

Large ground sheets or "drop cloths" are spread across the staging area. Since PVC coated fabric is susceptible to scuffing and dirt during the unfolding stage, maintaining a pristine environment is essential to ensure the final aesthetic is clean and professional.

Phase 2: Membrane Deployment and "The Big Pull"

Deploying the fabric is often the most visually dramatic part of the installation. For large-scale projects like stadium roofs or airport terminals, this requires synchronized cranes and a large crew of technicians.

- Unfolding: The tensile fabric is unrolled according to a specific sequence determined during factory folding to avoid trapping air or creating sharp creases.

- Hoisting: Using specialized fabric clamps and spreader beams, cranes lift the membrane into position.

- Temporary Fixings: The fabric is loosely attached to the main anchor points using "drifting" tools to align the bolt holes.

Phase 3: Final Tensioning and Stress Balancing

A PVC tensile fabric structure is only "structural" once it is under tension. Without proper tensioning, the fabric would flap in the wind, causing fatigue and eventual failure. This phase involves pulling the fabric to its pre-stress levels, typically ranging from 1.0 to 5.0 kN/m depending on the engineering requirements.

Mechanical Jacking and Winching

Technicians use hydraulic jacks or heavy-duty turnbuckles to pull the fabric toward the perimeter plates. This is done in increments to allow the fibers of the PVC coated fabric to settle and redistribute the stress evenly across the surface.

| Structure Size | Typical Tools | Tensioning Method |

|---|---|---|

| Small (Car Parks) | Hand Winches, Turnbuckles | Manual Thread Tightening |

| Medium (Walkways) | Tirfor Winches, Scaffolding | Sequential Perimeter Pull |

| Large (Stadiums) | Hydraulic Jacks, Cranes | Computer-Monitored Stressing |

Phase 4: Sealing, Weatherproofing, and Finishing

Once the PVC tensile fabric is under full tension, the final details are addressed to ensure a 100% waterproof finish. This is where the longevity of the structure is secured.

Installing the Weather Flashing

PVC flaps (often called "skirts") are welded or bolted over the connection joints. This prevents water from ingress at the points where the fabric meets the steel. In many PVC coated fabric systems, these flaps are hot-air welded on-site for a seamless look.

Torque Verification

All bolts and nuts used in the clamping bars are checked with torque wrenches. For a standard tensile structure, it is common to verify hundreds of bolts to ensure that no single point of the perimeter is under-tightened, which could lead to localized stress concentrations.

Essential Safety Factors During Installation

The installation of PVC tensile fabric is highly weather-dependent. Because the fabric acts like a giant sail before it is fully secured, wind speeds must be monitored constantly.

- Wind Limits: Installation usually stops if wind gusts exceed 25-30 km/h to prevent the fabric from becoming uncontrollable.

- Rope Access: Techs often use industrial climbing techniques (rope access) to reach the center of large spans without damaging the tensile fabric with heavy ladders.

- Wrinkle Removal: If wrinkles appear, it indicates uneven tension. The crew must adjust the opposing corner to balance the "warp and weft" of the fabric weave.

Following these rigorous steps ensures that the PVC tensile fabric remains stable and aesthetically pleasing for its entire 20-year lifespan.

English

English Español

Español русский

русский