Content

Direct Answer: The Core Composition of Tensile Fabric

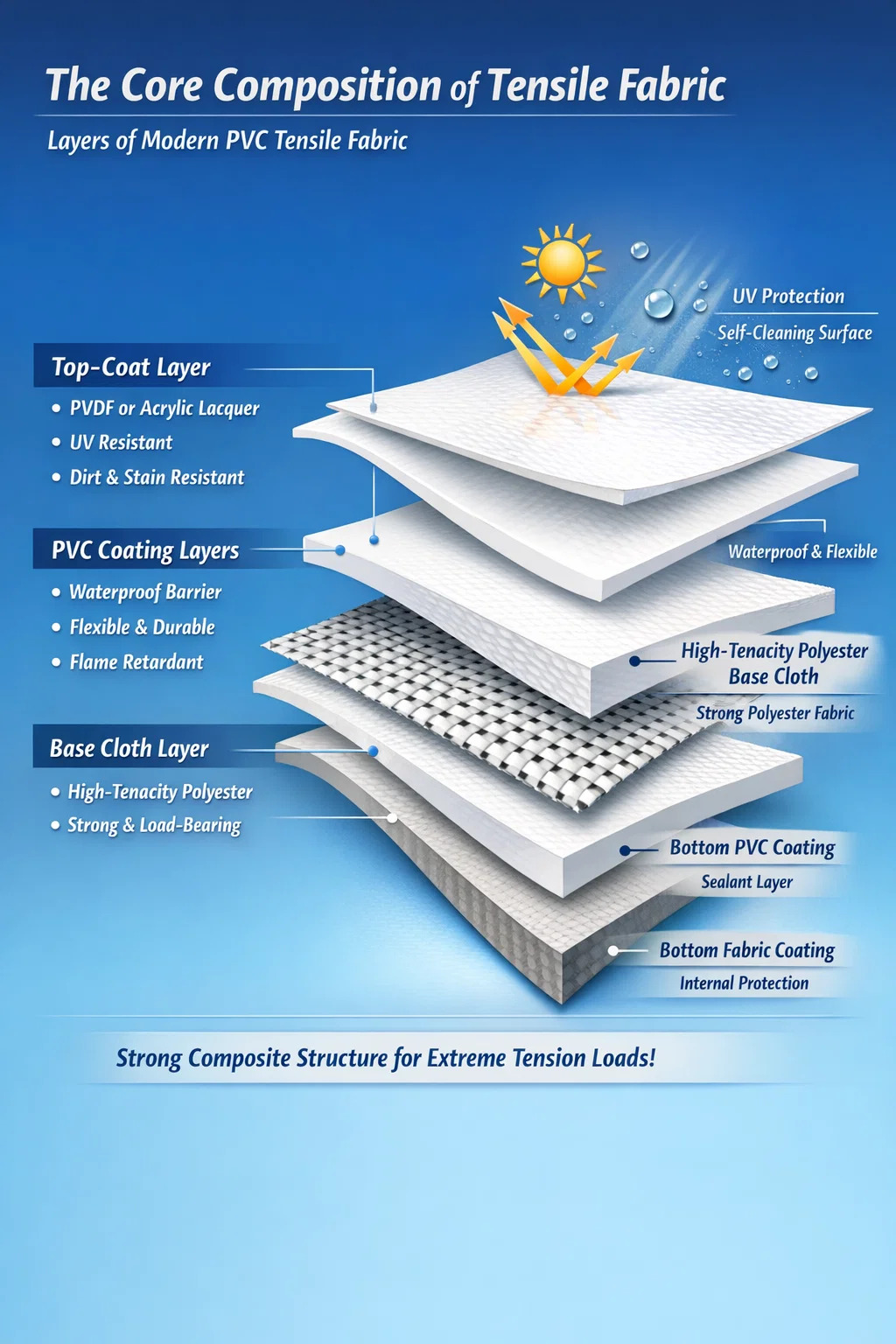

Most modern PVC tensile fabric is a sophisticated composite material consisting of three primary layers: a high-tenacity polyester base cloth, a thick PVC (Polyvinyl Chloride) coating, and a specialized top-coat lacquer such as PVDF or Acrylic. The inner fabric provides the structural strength to handle massive tension loads, while the outer plastic layers shield the fibers from environmental degradation, water, and fire.

The Structural Heart: High-Tenacity Base Cloth

The foundation of any PVC tensile fabric is the woven textile at its center. This is not ordinary cloth; it is engineered to withstand immense pulling forces without stretching excessively or tearing.

Polyester Fibers

Polyester is the industry standard for general-purpose tensile structures due to its excellent strength-to-cost ratio. These fibers are bundled into yarns and woven into a grid pattern. The "warp" (lengthwise) and "weft" (crosswise) yarns are often woven with different densities to manage specific architectural stresses.

Glass Fiber Alternatives

While less common in standard PVC coated fabric, glass fiber is used for permanent structures requiring extreme fire resistance. However, for most car parks, stadium roofs, and walkways, polyester remains the preferred choice because of its flexibility and ease of handling during installation.

The Protective Shield: PVC Coating Layers

Once the base cloth is ready, it is passed through a coating line where liquid PVC is applied. This turns a porous net into a solid, waterproof membrane.

- Polyvinyl Chloride (PVC): This layer acts as the primary binder. It fills the gaps between the woven yarns and creates a smooth, airtight surface.

- Plasticizers: Chemicals are added to the PVC to keep it flexible. Without these, the fabric would be too stiff to fold and would crack under wind pressure.

- UV Stabilizers: These additives prevent the sun from "cooking" the plastic, ensuring the material doesn't become brittle within a few years of outdoor exposure.

- Flame Retardants: Most tensile fabric materials are treated to meet strict fire safety codes, such as B1 or M2 ratings, ensuring they do not support active combustion.

Surface Top-Coatings: PVDF and Acrylic Lacquers

The outermost layer of a PVC tensile fabric is a very thin lacquer that determines how the fabric interacts with dirt and chemicals. This is the "face" of the material that you see and touch.

| Coating Type | Key Characteristics | Average Lifespan |

|---|---|---|

| Acrylic Lacquer | Low cost, easy to weld, standard gloss | 5 - 10 Years |

| PVDF (Weldable) | Good self-cleaning, high UV resistance | 10 - 15 Years |

| PVDF (Non-Weldable) | Premium self-cleaning, requires grinding to weld | 15 - 25 Years |

Essential Properties Derived from Materials

The combination of these specific raw materials gives PVC tensile fabric its unique physical properties. For example, a standard 900g/m² membrane has a tensile strength of roughly 4000 N/5cm, which is vastly stronger than traditional canvas.

Translucency

By controlling the ratio of PVC and the weave of the polyester, manufacturers can adjust light transmission. Most white membranes allow 5% to 15% of natural light to pass through, creating a soft, shadow-free environment underneath without the heat gain of glass.

Wick Resistance

Quality PVC coated fabric uses "low-wick" yarns. These fibers are treated so that if the coating is scratched, water cannot travel through the core of the yarn by capillary action. This prevents internal rot and unsightly brown staining from developing inside the material over time.

Summary of Material Layers

To visualize how tensile fabric is put together, consider the following sequence of layers from bottom to top:

- Bottom Top-Coat (for internal aesthetics)

- Bottom PVC Layer (waterproofing and protection)

- Base Fabric (the load-bearing polyester weave)

- Top PVC Layer (the bulk of the environmental shield)

- Top-Coat Finishing Lacquer (the self-cleaning PVDF layer)

English

English Español

Español русский

русский