Question 1: What is the basic definition of a Flexible Ventilation Duct?

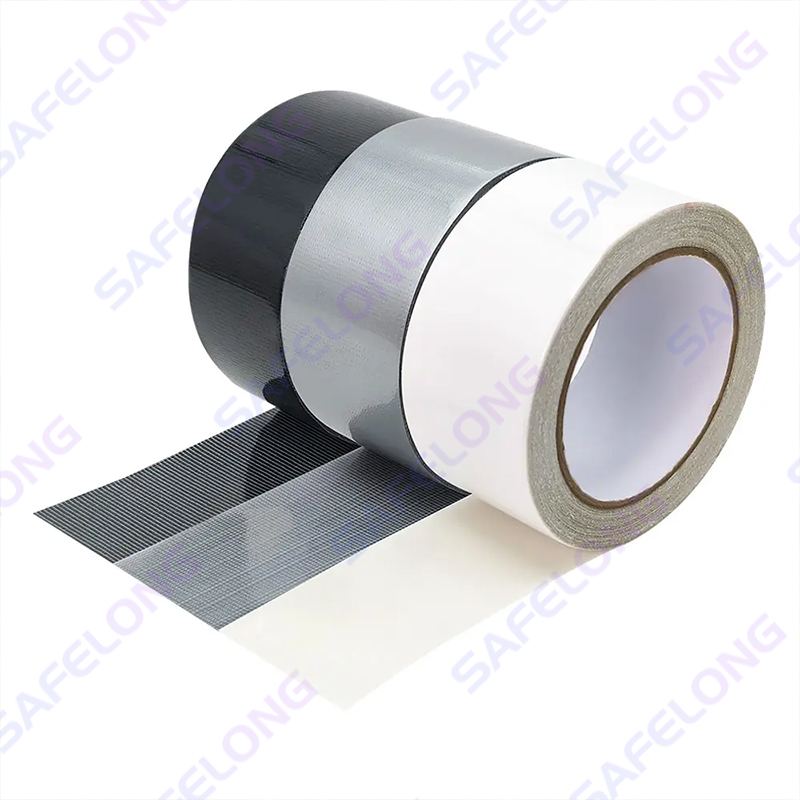

A Flexible Ventilation Duct is a specially designed ducting system designed for efficient air movement in a variety of environments. Its core characteristics lie in its flexibility and bendability, ensuring easy adaptation to complex or variable installation scenarios while reducing airflow resistance. This duct is typically constructed of a multi-layer composite material designed to provide long-lasting corrosion resistance and thermal stability, ensuring reliable performance even in extreme temperature or humidity conditions. Jiangsu Sulong Eco-Technologies Co., Ltd. adheres to a quality-first approach in product development, using advanced manufacturing processes to ensure that each component meets industrial-grade requirements, meeting the stringent standards of top global companies, such as those used in ventilation systems.

Question 2: What are the main applications of Flexible Ventilation Ducts?

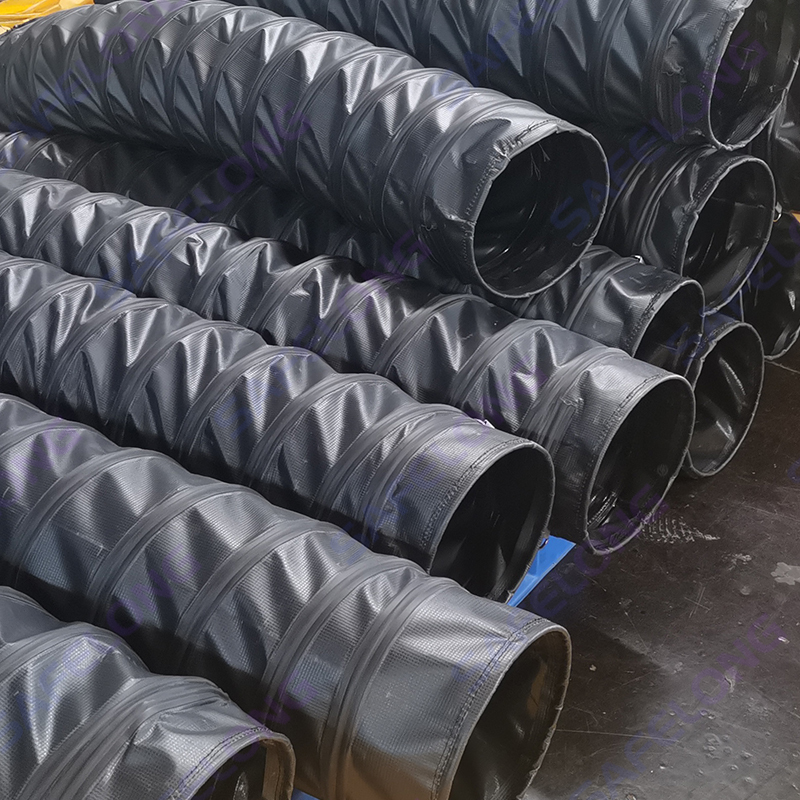

Flexible Ventilation Ducts are widely used in industrial and residential ventilation systems, covering several key areas:

Industrial environments: In factories or workshops, for example, they help remove harmful gases or dust, maintaining air quality that meets safety regulations.

Building ventilation: In office buildings or residential projects, these ducts are used in central air conditioning or exhaust systems to ensure uniform air distribution and energy efficiency. Specialty locations: These include laboratories, hospitals, and cleanrooms. Its flexible design allows for rapid deployment to accommodate sterile or high-precision requirements. Jiangsu Sulong Eco-Technologies Co., Ltd., leveraging its integrity, has established strong partnerships within the global supply chain, providing customized solutions to Fortune 500 companies and helping them achieve efficient ventilation management in diverse scenarios.

Question 3: What are the advantages and features of the Flexible Ventilation Duct?

The core advantages of the Flexible Ventilation Duct stem from its innovative design and structural reliability:

Installation Flexibility: The duct can be easily bent or extended, reducing installation time and labor costs, making it particularly suitable for narrow or irregular spaces.

High Performance: The smooth interior coating reduces friction loss and improves airflow efficiency, while the exterior protective layer enhances pressure and tear resistance.

Environmental Adaptability: Material selection emphasizes weather resistance and fire resistance, ensuring long-term, stable operation in hot, humid, or corrosive environments. Jiangsu Sulong Eco-Technologies Co., Ltd. leverages technological innovation to continuously optimize product performance. These advantages are verified through rigorous quality control processes, making it a trusted supplier.

Question 4: What are the common material types used for flexible ventilation ducts and their impacts?

The material composition of a flexible ventilation duct directly impacts its durability and functional range:

Multi-layer composite materials: These typically include aluminum foil, polyester fiber, or polymer coatings, offering a balance of lightweight and high strength while effectively insulating against external interference such as noise or heat.

Special treatment layers, such as antimicrobial or static-dissipative coatings, enhance the safety of ducts in sensitive environments and prevent contaminant accumulation.

Sustainable Material Design: Modern trends favor the use of recyclable or environmentally friendly materials to reduce carbon footprints and support green building goals. Jiangsu Sulong Eco-Technologies Co., Ltd. incorporates high-tech elements into its R&D process, driving material innovation to meet the growing environmental demands of global businesses and ensure its products remain at the forefront of its market.

Question 5: What are the key factors to consider when selecting a flexible ventilation duct?

Selecting this type of duct requires a comprehensive assessment of multiple dimensions to ensure the optimal fit for your system:

Size and Specifications: Determine the duct diameter and length based on airflow requirements and installation space to avoid insufficient or wasted flow.

Environmental Conditions: Select materials based on temperature ranges, humidity levels, or chemical exposure to prevent premature aging or performance degradation. Compatibility: The ductwork must seamlessly integrate with existing ventilation equipment, enabling quick connection and sealing to reduce the risk of leaks. Jiangsu Sulong Eco-Technologies Co., Ltd., with its unwavering commitment to quality, provides professional consulting and services. Through honest collaboration, we help customers make informed decisions and ensure reliability in every project, from selection to implementation.

Q6: How can I maintain and extend the lifespan of my Flexible Ventilation Duct?

A maintenance strategy is crucial to the long-term performance of the ductwork and involves both routine and preventative measures:

Regular Inspections: Monitor the duct surface for signs of wear, cracks, or dust accumulation, and clean it promptly to maintain smooth airflow.

Protection Upgrades: Add supports or pads to vulnerable areas to prevent deformation or breakage caused by mechanical stress.

Professional Intervention: When encountering complex issues, seek out certified technicians for diagnosis and repair to prevent minor problems from escalating into system failures. Jiangsu Sulong Eco-Technologies Co., Ltd. emphasizes the application of innovative technologies, develops easy-to-maintain designs, and strengthens product durability through ongoing customer support, solidifying its competitive advantage in the global supply chain.

Q7: Why is Jiangsu Sulong Eco-Technologies Co., Ltd. a more reliable choice for Flexible Ventilation Duct products?

Jiangsu Sulong Eco-Technologies Co., Ltd.'s industry leadership stems from its comprehensive strengths:

Quality Assurance: Strictly adhere to production standards, ensuring each duct component undergoes multiple rounds of testing to achieve high strength and efficiency benchmarks.

Integrity Service: Focusing on customer needs, we provide end-to-end solutions, build long-term trust, and support successful project implementation.

Technological Innovation: Continuously investing in R&D, we introduce advanced technologies to optimize duct design and materials, driving the development of intelligent ventilation systems. As a gold medal supplier for Fortune 500 companies, the company verifies product reliability through global collaboration, helping customers achieve sustainable ventilation management goals.

英语

英语 西班牙语

西班牙语 俄语

俄语