Q: What is the core innovative concept of Innovative Fabric and Duct Products?

A:

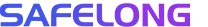

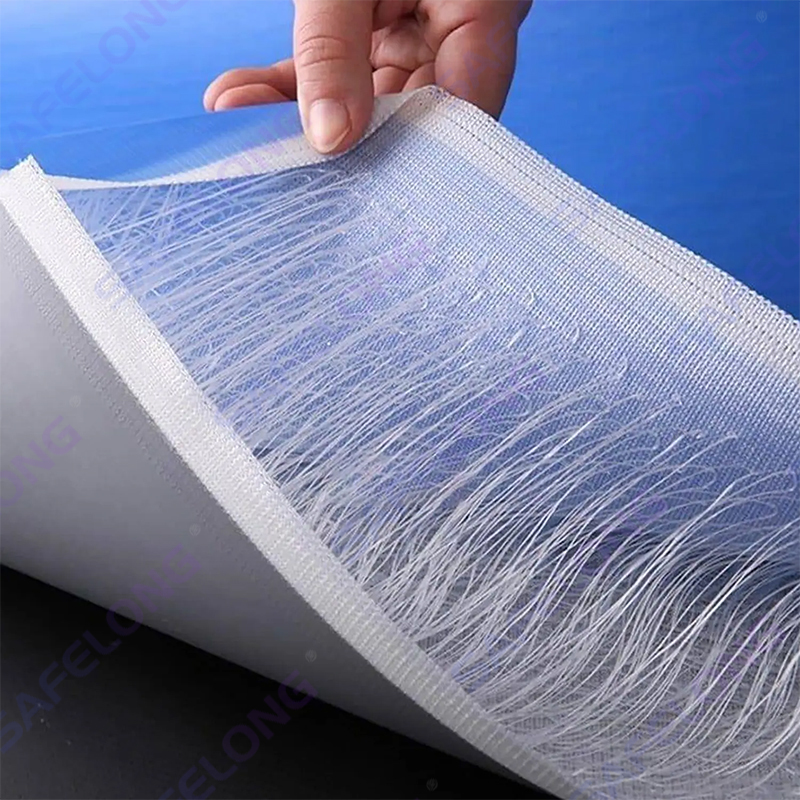

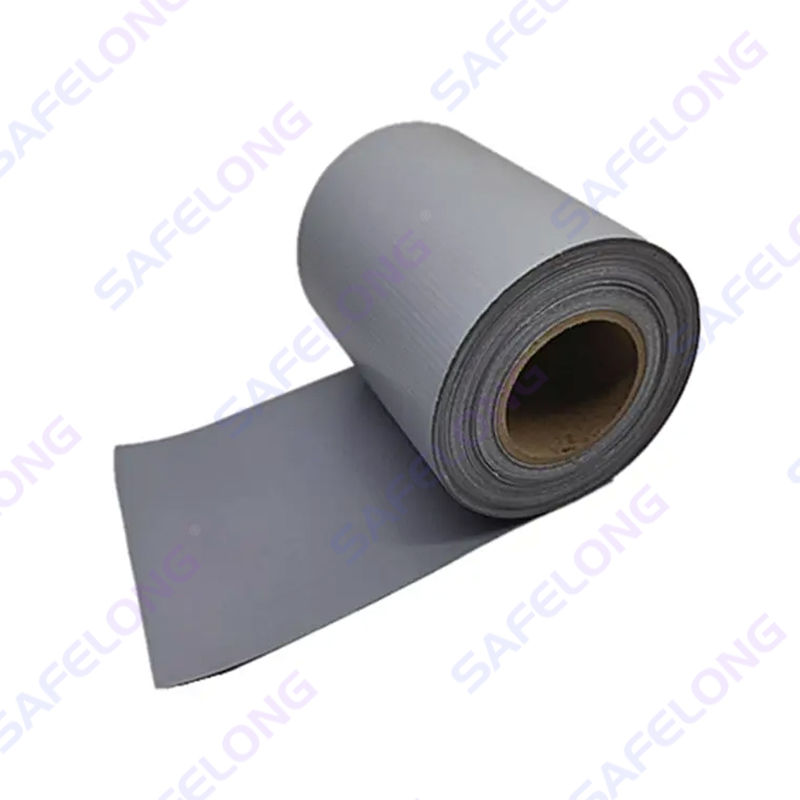

These products are built at the intersection of materials science and engineering technology, emphasizing the functional application of high-molecular-weight polymers. Unique coating and lamination processes enhance the fabric's airtightness, durability, and environmental performance. For example, optimized treatment of PVC and PE substrates achieves effective gas barrier properties and chemical stability, making them suitable for demanding environmental control applications.

The innovative concept is reflected in intelligent integration during the design phase, such as utilizing automated production systems to achieve integrated molding of fabric and ducting, reducing joints and gaps and thus improving overall sealing performance. This approach stems from long-standing practical challenges in the industrial ventilation and environmental protection fields, effectively avoiding the corrosion and frequent maintenance issues of traditional metal ducting.

Combined with Sulong Environmental Protection's R&D experience, the company transforms theoretical research from universities into practical innovations through industry-university-research collaborations. For example, environmentally friendly additives are added to the fabric formula to enhance its resistance to aging and degradation, ensuring the product's sustainable application in mine ventilation and tunneling projects.

Q: What are the key advantages of Innovative Fabric and Duct Products in the environmental and industrial fields?

A:

The primary advantage lies in environmental adaptability. These products utilize lightweight yet high-strength fabric structures, capable of withstanding extreme temperatures, humidity, and chemical environments without the need for additional reinforcement. For example, polymer-coated fabrics effectively isolate contaminants in waterproofing and anti-seepage applications, reducing the risk of secondary contamination of soil and water.

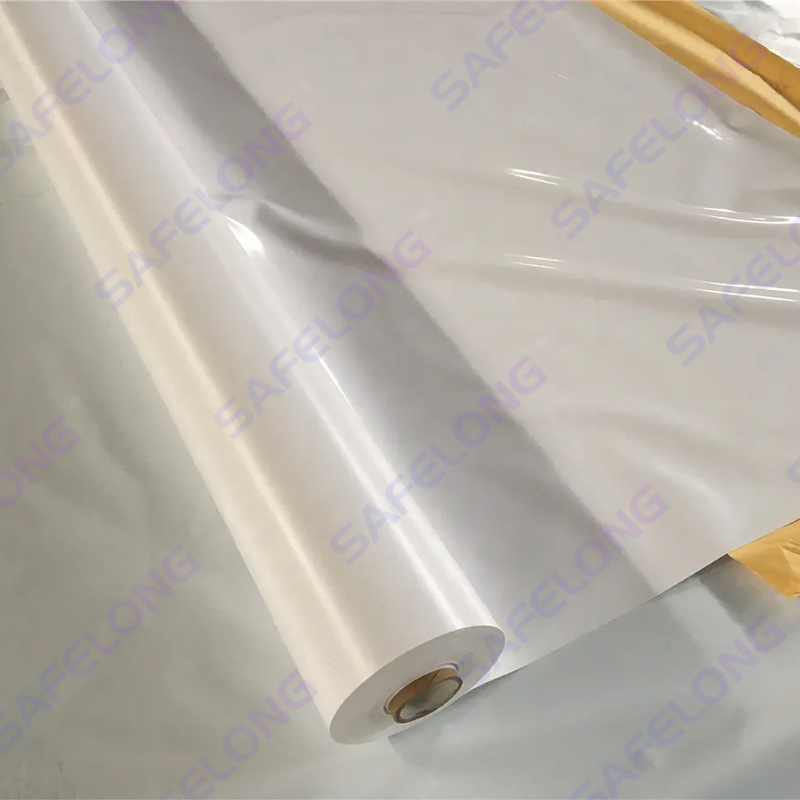

Another key advantage is improved operational efficiency. The modular design simplifies installation and maintenance, reducing construction time and resource consumption. In ventilation systems, the flexibility of flexible fabric ducting allows for customized layouts, optimizes airflow distribution, and improves energy efficiency, which is critical for achieving emission reduction goals in large industrial facilities.

Sulong Environmental Protection's practices reinforce these advantages. The company specializes in the development of ventilation solutions for mines and tunnels. Its patented technology ensures its products maintain tightness and durability in complex geological conditions while supporting circular economy principles, such as reducing waste through recyclable materials.

Q: What role does Sulong Environmental Protection play in promoting technological innovation in Innovative Fabric and Duct Products?

A:

The company leads technological innovation through independent research and development and collaboration with universities, establishing a complete innovation chain. For example, its intelligent production line utilizes advanced processes such as dual-die casting, significantly improving the uniformity and bond strength of fabric coatings, ensuring the products meet high industry standards for airtightness and mechanical properties.

In terms of patent portfolio, Sulong Environmental Protection's core innovation focuses on one-step molding technology, which solves the leakage problems caused by traditional fabric duct splicing. This technological breakthrough not only reduces production costs but also improves product consistency and reliability, making it suitable for large-scale environmental protection projects such as wastewater treatment or dust control.

Industry-university-research collaboration is a key strategy for the company. Basic research conducted in collaboration with institutions such as Sichuan University has driven the development of new fabric materials. For example, the optimization of polyester fiber composite materials has enhanced UV and fire resistance, indirectly driving the evolution of industry standards towards more environmentally friendly and efficient products.

Q: What are the key aspects of the technological advancement of Innovative Fabric and Duct Products?

A:

Advances in materials science are at the core. By manipulating the molecular structure of polymers, the multifunctionality of fabrics is achieved. For example, the composite treatment of PVC and PE substrates imparts excellent chemical and abrasion resistance, enabling long-term stable operation in high humidity or acidic and alkaline environments. Innovations in production processes have brought significant breakthroughs. For example, one-step molding eliminates the multi-step drawbacks of traditional manufacturing, ensuring seamless and uniformly airtight fabric ducts. This not only reduces energy loss but also improves overall system safety, particularly in ventilation applications, preventing the leakage of hazardous gases.

Combining Sulong Environmental Protection's engineering experience, the company has incorporated these technologies into practical solutions. For example, an intelligent control system is used in tunnel ventilation systems to monitor the condition of fabric ducts in real time and automatically adjust according to environmental changes, reflecting the industrial trend of integrating automation and intelligence.

Q: Based on Sulong Environmental Protection's industry experience, what are the future development trends for Innovative Fabric and Duct Products?

A:

Sustainability will become a dominant direction, with a focus on the use of bio-based materials and biodegradable coatings to reduce carbon footprint. For example, by developing environmentally friendly additives and improving recycling processes, product lifecycles are being extended, in line with the global trend of green manufacturing.

Intelligent and digital integration is another trend. Future products will be embedded with sensors and IoT technology to enable real-time data collection and predictive maintenance. This evolution stems from Sulong Environmental Protection's experience in automated production lines. For example, its intelligent units use AI-assisted optimization of production parameters, improving resource efficiency and product customization capabilities. Cross-domain integration will drive widespread application, expanding from traditional ventilation systems to emerging areas such as urban underground engineering and disaster prevention. Sulong Environmental Protection's experience in mining and tunneling projects has laid the foundation for this. Through continuous innovation, the company ensures its products provide reliable protection in high-risk environments, helping to build a safer industrial ecosystem.

英语

英语 西班牙语

西班牙语 俄语

俄语