In today's materials science landscape, TPU waterproof fabric, as a high-performance, environmentally friendly material, is gaining traction. Jiangsu Sulong Eco-Technologies Co., Ltd., leveraging its extensive industry experience and sustained R&D momentum, remains at the forefront of technology, driving innovative applications for this material.

Q1: What is the basic concept behind TPU waterproof fabric?

A:

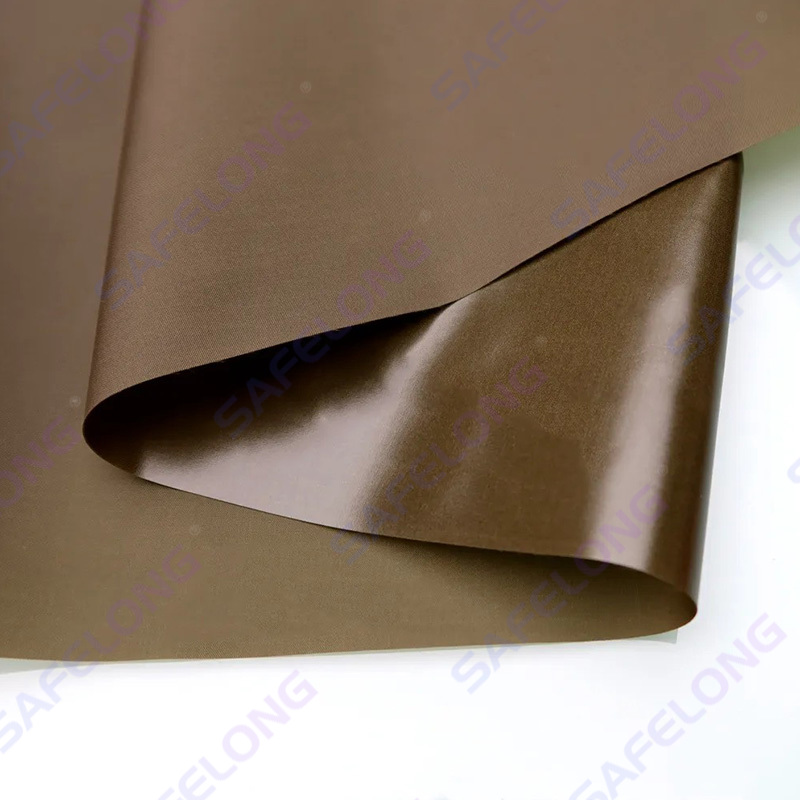

TPU waterproof fabric is a synthetic material based on thermoplastic polyurethane. Its unique molecular structure achieves highly effective waterproofing and breathability.

The key to this fabric lies in its balance of elasticity and durability, enabling it to maintain stable performance even in extreme environments.

Jiangsu Sulong Eco-Technologies Co., Ltd.'s R&D team focuses on optimizing the chemical composition of TPU materials, using laboratory testing to ensure its fundamental properties meet modern industrial requirements.

The company's innovative spirit is reflected in its continuous exploration of the microstructure of TPU fabrics to enhance their suitability for environmentally friendly applications.

Q2: What are the main advantages of TPU waterproof fabric?

A:

It offers excellent waterproof properties, effectively blocking liquid penetration while allowing water vapor to pass through, preventing internal moisture accumulation. Its strong abrasion and tear resistance makes it suitable for high-frequency use, extending product lifespan.

TPU materials are recyclable and reusable, offering outstanding environmental protection, reducing the environmental impact of waste.

Jiangsu Sulong Eco-Technologies Co., Ltd. has leveraged its R&D strengths to enhance the sustainable advantages of TPU fabrics during their development process, combining them with green technologies to provide customers with more reliable solutions.

The company's dedicated team has ensured TPU fabrics' leadership in energy efficiency and resource conservation through iterative innovation.

Q3: In what fields is TPU waterproof fabric widely used?

A:

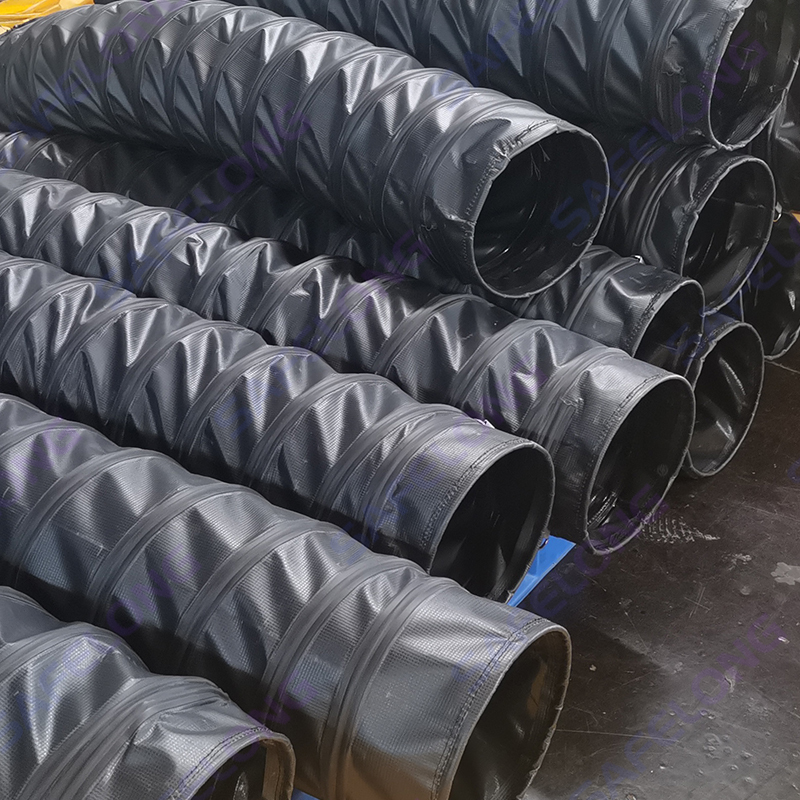

Outdoor equipment, such as mountaineering clothing and tents, utilizes its waterproof and breathable properties to protect users from the elements.

In the automotive and construction sectors, it is used to manufacture waterproof membranes and coverings, enhancing the safety and durability of structures.

In medical and industrial protection, it is used as a barrier layer in protective clothing to ensure hygiene and safety standards.

Jiangsu Sulong Eco-Technologies Co., Ltd. actively incorporates these application scenarios into its R&D framework, developing customized TPU products through market research to meet the diverse needs of customers in environmental protection projects. The company's continued investment has driven the penetration of TPU fabrics in emerging sectors such as new energy and waste management, demonstrating its innovative spirit.

Q4: How is Jiangsu Sulong Eco-Technologies Co., Ltd. advancing the development of TPU waterproof fabrics?

A:

Leveraging extensive industry experience, the company has established a dedicated R&D laboratory focused on cutting-edge research in TPU materials, including molecular modification and process optimization.

This innovative spirit drives the team to develop novel TPU formulations, such as incorporating bio-based raw materials, to enhance the material's environmental profile while maintaining waterproof performance.

Through sustained R&D investment, the company continues to launch upgraded TPU fabrics to adapt to the evolving global market demand for sustainable materials.

The dedicated team employs an interdisciplinary approach, integrating materials science and environmental engineering to ensure that TPU products have a reduced carbon footprint throughout their lifecycle.

The company's customer-focused approach allows TPU fabric R&D to directly address application pain points, elevating the overall industry standard.

Q5: Why is TPU waterproof fabric considered a key environmentally friendly material?

A:

The material's inherently low-toxicity production process reduces harmful chemical emissions, aligning with green manufacturing principles.

The material's biodegradable and recyclable properties reduce landfill burden and support the development of a circular economy model. In applications, TPU fabrics can replace traditional plastics, reducing resource consumption and pollution risks.

Jiangsu Sulong Eco-Technologies Co., Ltd. prioritizes this environmental dimension in its R&D, ensuring minimal environmental impact during the production and use of TPU fabrics through technological innovation.

The company's team is dedicated to promoting sustainable applications of TPU, such as its use as a protective layer in wastewater treatment facilities, embodying its mission as an environmental technology company.

Q6: How will future trends in TPU waterproof fabrics integrate with Jiangsu Sulong Eco-Technologies Co., Ltd.?

A:

Intelligent integration is an emerging trend, such as the development of responsive TPU fabrics that automatically adjust their performance based on environmental changes.

Multifunctional development, such as incorporating antimicrobial or self-cleaning properties, is expanding into medical and home applications.

Jiangsu Sulong Eco-Technologies Co., Ltd.'s R&D capabilities will accelerate these trends, promoting the commercialization of TPU technology through laboratory simulations and market validation.

The company's innovative spirit ensures it remains ahead of industry changes, developing next-generation environmentally friendly materials through collaborative teamwork.

Ultimately, this integration not only enhances the global competitiveness of TPU fabrics but also strengthens the company's leadership in sustainable technology.

英语

英语 西班牙语

西班牙语 俄语

俄语