In the world of modern architecture and construction, materials that combine strength, durability, and aesthetic appeal are highly sought after. One such material is PVC Tensile Fabric, a versatile and innovative solution used in a wide range of applications. This guide is designed to provide a comprehensive overview of PVC Tensile Fabric, from its properties and manufacturing to its applications and market dynamics. Whether you are a buyer, architect, engineer, or simply someone interested in this fascinating material, this guide aims to provide a thorough understanding of what PVC Tensile Fabric is, how it works, and why it is a preferred choice in many industries.

Content

- 1 What is PVC Tensile Fabric?

- 2 How is PVC Tensile Fabric Made?

- 3 Applications of PVC Tensile Fabric

- 4

- 5 Buyer’s Guide: Key Considerations for Purchasing PVC Tensile Fabric

- 5.1 1. Material Specifications and Quality

- 5.2 2. Performance Characteristics

- 5.3 3. Application-Specific Requirements

- 5.4 4. Cost and Budget

- 5.5 5. Supplier and Manufacturer Reliability

- 5.6 6. Certifications and Standards

- 5.7 7. Installation and Support

- 5.8 8. Environmental and Sustainability Considerations

- 6

- 7 Installation and Construction Process

- 8 Maintenance and Longevity

- 9 Environmental and Sustainability Considerations

- 10

- 11 Challenges and Limitations

- 12 Frequently Asked Questions (FAQs) about PVC Tensile Fabric

- 12.0.1 Q1: What is PVC Tensile Fabric?

- 12.0.2 Q2: What are the main applications of PVC Tensile Fabric?

- 12.0.3 Q3: What are the key advantages of PVC Tensile Fabric?

- 12.0.4 Q4: How is PVC Tensile Fabric manufactured?

- 12.0.5 Q5: What are the common challenges associated with PVC Tensile Fabric?

- 12.0.6 Q6: How long does PVC Tensile Fabric last?

- 12.0.7 Q7: Is PVC Tensile Fabric environmentally friendly?

- 12.0.8 Q8: Can PVC Tensile Fabric be repaired or replaced?

- 12.0.9 Q9: What are the installation requirements for PVC Tensile Fabric?

- 12.0.10 Q10: What are the future trends in PVC Tensile Fabric?

- 13 Case Studies and Real-World Applications

- 14

- 15 Future Developments and Innovations

- 16 Global Market and Industry Trends

- 17 Sustainability and Environmental Impact

- 18 Future Outlook and Predictions

What is PVC Tensile Fabric?

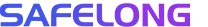

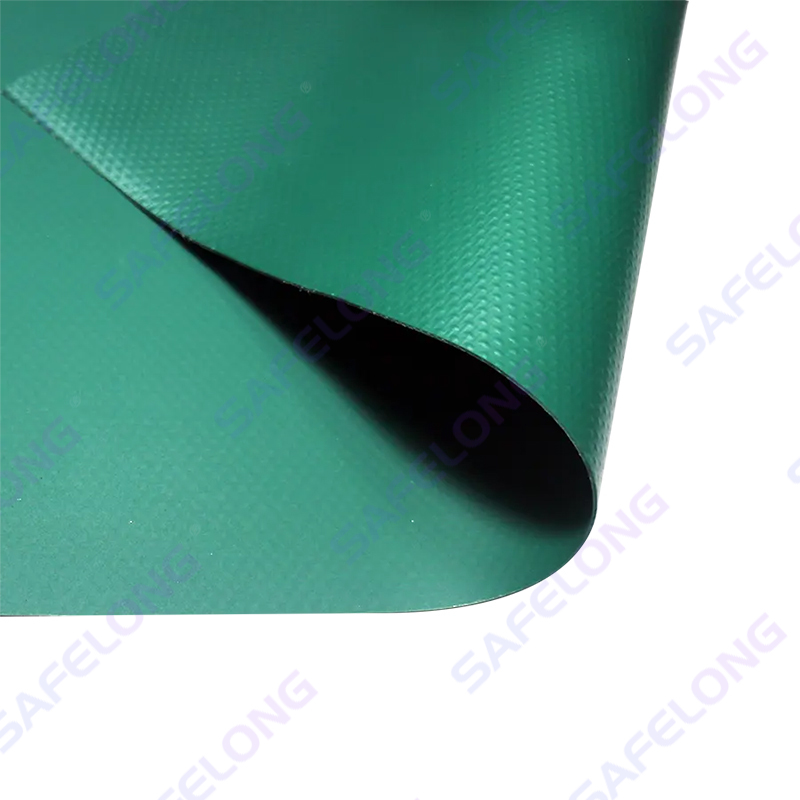

PVC Tensile Fabric is a high-performance material that combines the strength of a base fabric (such as polyester or glass fiber) with the durability and weather resistance of a PVC (Polyvinyl Chloride) coating. This combination results in a material that is both strong and flexible, making it ideal for a wide range of applications.

Key Characteristics of PVC Tensile Fabric

| Feature | Description |

| High Strength | PVC Tensile Fabric exhibits high tensile strength, making it suitable for mid-to-high-end tensile membrane structures . |

| Durability and Weather Resistance | PVC Tensile Fabric is known for its excellent weather resistance, UV resistance, and ability to withstand environmental factors such as UV radiation and moisture . |

| Flexibility and Plasticity | The material is highly flexible and can be shaped and tensioned to form complex structures, making it ideal for architectural and temporary structures . |

| Water Resistance | PVC Tensile Fabric is highly water-resistant, making it suitable for applications where moisture barriers are required . |

| Chemical Resistance | PVC is highly resistant to a variety of chemicals, including acids, alkalis, and oils, making it suitable for a wide range of applications . |

| Longevity | While not as long-lasting as some high-end materials like PTFE, PVC Tensile Fabric offers a good balance of performance and cost-effectiveness . |

| Applications | Common applications include architectural structures (shades, canopies, roofs), sports facilities, commercial buildings, and temporary structures . |

| Flame Retardant | Some products are available in FR grade, conforming to DIN 4102-81 standards . |

| UV Resistance | Products undergo UV and outdoor weathering tests, ensuring high UV stability and passing UV 801 with UPF80 Class . |

| Minimal Warp to Weft Elongation | The wet extension process ensures minimal variation in linear and cross-directional elongation . |

How is PVC Tensile Fabric Made?

The production of PVC Tensile Fabric involves several steps, each of which contributes to the final product's quality and performance.

1. Fabric Selection

The base fabric is typically made from materials such as polyester or glass fiber. The choice of fabric depends on the specific application and the desired properties of the final product.

2. Coating Process

The base fabric is then coated with PVC. This can be done through various methods, including extrusion, lamination, or spraying. The coating process ensures that the fabric is protected and enhanced with the properties of PVC.

3. Quality Control

Quality control is a critical step in the production process. Each stage of production is monitored to ensure that the final product meets the required standards of strength, durability, and performance.

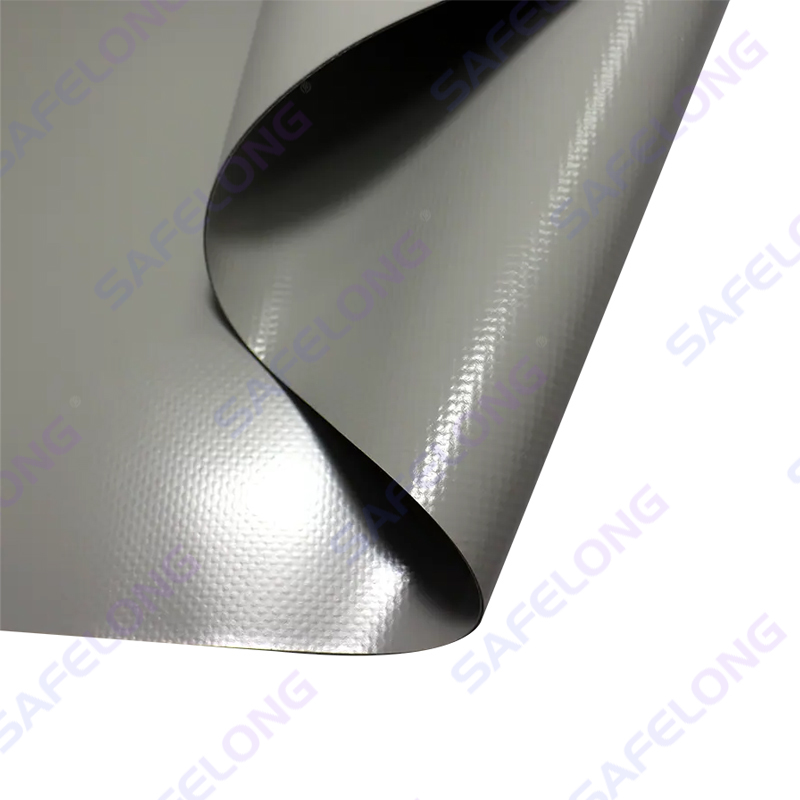

4. Finishing and Packaging

After the coating process, the fabric is cut, shaped, and packaged for distribution. This ensures that the product is ready for use in various applications.

| Step | Description |

| Fabric Selection | PVC Tensile Fabric is typically made from a base fabric (such as polyester or glass fiber) coated with PVC (Polyvinyl Chloride) . |

| Coating Process | The base fabric is coated with one or more layers of PVC material. This coating process is often done through a method called calendaring, where the PVC material is extruded and rolled into a flat sheet . |

| Quality Control | Quality control is essential during the manufacturing process to ensure the final product meets performance standards. This includes checking for consistency in thickness, strength, and durability . |

| Joining Methods | The fabric can be joined using various methods, including welding (radio frequency welding), sewing, or gluing, depending on the application and requirements . |

| Finishing | The final product may undergo additional treatments, such as UV stabilization or color customization, to enhance its performance and longevity . |

Applications of PVC Tensile Fabric

PVC Tensile Fabric is used in a wide range of applications across various industries. Its unique combination of strength, durability, and flexibility makes it suitable for a variety of uses.

1. Architectural Applications

PVC Tensile Fabric is widely used in architectural applications, such as:

- Canopies and Roofs: The fabric is used to create lightweight and durable roofing solutions for buildings and structures.

- Shades and Awnings: PVC Tensile Fabric is used to create functional and aesthetic shading solutions for outdoor spaces.

- Facade Cladding: The fabric can be used to create visually striking and functional facade cladding for buildings.

2. Sports and Recreation

PVC Tensile Fabric is also used in sports and recreational applications, such as:

- Sports Facilities: The fabric is used in the construction of sports facilities, such as tennis courts, basketball courts, and swimming pool covers.

- Temporary Structures: PVC Tensile Fabric is used in the construction of temporary structures, such as event tents and temporary shelters.

3. Commercial and Industrial Applications

PVC Tensile Fabric is also used in commercial and industrial applications, such as:

- Industrial Canopies: The fabric is used to create protective canopies for industrial facilities.

- Storage and Warehousing: PVC Tensile Fabric is used in the construction of storage and warehousing facilities.

4. Temporary and Emergency Structures

PVC Tensile Fabric is also used in the construction of temporary and emergency structures, such as:

- Emergency Shelters: The fabric is used in the construction of emergency shelters and temporary housing.

- Disaster Relief: PVC Tensile Fabric is used in disaster relief efforts to provide temporary shelter and protection.

| Application | Description |

| Architectural Structures | PVC Tensile Fabric is widely used in architectural structures such as canopies, walkways, atrium coverings, and facades. These structures provide shade, weather protection, and aesthetic appeal to public spaces, commercial buildings, and residential complexes . |

| Sports Facilities | The fabric is used to cover sports facilities like stadiums, swimming pools, tennis courts, and gymnasiums to provide shelter for athletes and spectators while maintaining an open and airy environment . |

| Commercial Spaces | PVC Tensile Fabric is used in shopping malls, hotels, restaurants, and retail outlets to create visually striking ceilings, partitions, and decorative elements that enhance the overall ambiance of the space . |

| Event Venues | The fabric is popular for creating temporary event venues such as exhibition halls, trade show pavilions, concert stages, and wedding marquees . |

| Transportation | PVC Tensile Fabric is utilized in automotive interiors such as panels and seats . |

| Marine Applications | The fabric is employed for both interior and exterior upholstery on vessels . |

| Health and Safety | Incorporated into healthcare settings and for the fabrication of protective clothing . |

| Hospitality & Home | Chosen for its resilience in furniture upholstery . |

| Recreation & Shelter | Integral to tents and athletic equipment . |

| Commercial Applications | Utilized for luggage, bags, and construction applications such as tarps . |

| Tensile Membrane Structures | PVC membrane structure fabric is used to create tensile membrane structures, such as canopies, tents, and roofs . |

Buyer’s Guide: Key Considerations for Purchasing PVC Tensile Fabric

As a buyer, understanding the key factors that influence the selection and purchase of PVC Tensile Fabric is crucial. This guide outlines the essential considerations that buyers should take into account when making purchasing decisions.

1. Material Specifications and Quality

The quality of PVC Tensile Fabric is determined by several factors, including the base fabric, the coating process, and the overall manufacturing quality.

- Base Fabric: The choice of base fabric (e.g., polyester or glass fiber) affects the strength, durability, and flexibility of the final product. Buyers should inquire about the type and quality of the base fabric used.

- Coating Process: The coating process (e.g., extrusion, lamination, or spraying) impacts the performance and longevity of the fabric. Buyers should ask about the specific coating technology used.

- Quality Control: Inquire about the manufacturer’s quality control procedures, including testing standards and certifications.

2. Performance Characteristics

Understanding the performance characteristics of PVC Tensile Fabric is essential for ensuring it meets the requirements of the intended application.

- Tensile Strength: The tensile strength of the fabric is a key performance indicator. Buyers should request data on the tensile strength of the product.

- Durability and Weather Resistance: The ability of the fabric to withstand environmental factors such as UV radiation, moisture, and temperature fluctuations is important. Buyers should inquire about the fabric’s resistance to these factors.

- Flexibility and Lightweight: The flexibility and lightweight nature of the fabric make it suitable for various applications. Buyers should consider how these properties affect the installation and use of the product.

3. Application-Specific Requirements

The intended application of the PVC Tensile Fabric plays a significant role in the selection process.

- Architectural Applications: For architectural applications such as canopies, roofs, and facade cladding, buyers should consider the aesthetic appeal, durability, and performance requirements.

- Sports and Recreation: For sports and recreational applications, buyers should consider the need for durability, safety, and functionality.

- Commercial and Industrial Applications: For commercial and industrial applications, buyers should consider the need for protection, durability, and cost-effectiveness.

- Temporary and Emergency Structures: For temporary and emergency structures, buyers should consider the need for rapid deployment, durability, and reliability.

4. Cost and Budget

The cost of PVC Tensile Fabric is a significant factor in the purchasing decision. Buyers should consider the total cost of the product, including materials, installation, and maintenance.

- Material Cost: The cost of the PVC Tensile Fabric itself is a primary consideration. Buyers should compare prices from different suppliers.

- Installation and Maintenance Costs: Buyers should consider the cost of installation and ongoing maintenance, including any specialized equipment or expertise required.

- Long-Term Value: Buyers should consider the long-term value of the product, including its durability and performance over time.

5. Supplier and Manufacturer Reliability

The reliability and reputation of the supplier and manufacturer are important factors in the purchasing decision.

- Supplier Reliability: Buyers should inquire about the supplier’s reputation, experience, and customer service. A reliable supplier can provide support and assistance throughout the purchasing and installation process.

- Manufacturer Reputation: Buyers should consider the reputation of the manufacturer, including their history of quality, innovation, and customer satisfaction.

6. Certifications and Standards

Certifications and standards provide assurance of the quality and performance of the product.

- Industry Standards: Buyers should inquire about the product’s compliance with relevant industry standards and regulations.

- Certifications: Buyers should look for certifications such as ISO 9001 (quality management), ISO 14001 (environmental management), and other relevant certifications.

7. Installation and Support

The installation and support services provided by the supplier and manufacturer are important considerations.

- Installation Services: Buyers should inquire about the availability of installation services, including technical support and training.

- Technical Support: Buyers should consider the availability of technical support and expertise to ensure proper installation and maintenance.

8. Environmental and Sustainability Considerations

Environmental and sustainability considerations are increasingly important in the purchasing decision.

- Sustainability: Buyers should consider the environmental impact of the product, including the use of recycled materials and sustainable manufacturing practices.

- Waste Management: Buyers should inquire about the manufacturer’s approach to waste management and recycling.

| Consideration | Description |

| Material Quality | The quality of the PVC Tensile Fabric is crucial. It should be made from a high-strength base material (e.g., polyester or glass fiber) and coated with PVC to ensure durability and performance . |

| Performance Characteristics | Key performance characteristics include tensile strength, weather resistance, UV resistance, and water resistance. These properties are essential for long-term performance in various environmental conditions . |

| Supplier and Manufacturer | The choice of manufacturer and supplier is important. Reputable manufacturers like Serge Ferrari Group, Mehler Technologies, and others are known for producing high-quality PVC Tensile Fabric . |

| Application Requirements | The specific application (e.g., architectural structures, sports facilities, or temporary venues) will influence the choice of fabric. Different applications may require different performance characteristics . |

| Cost and Budget | The cost of PVC Tensile Fabric varies based on material quality, thickness, and customization. It is important to balance cost with performance requirements . |

| Installation and Maintenance | Consider the ease of installation and maintenance. Some fabrics may require specific installation techniques or maintenance to ensure longevity . |

| Environmental Factors | Environmental conditions such as UV exposure, temperature fluctuations, and humidity can affect the performance of the fabric. Choosing a fabric with appropriate resistance to these factors is important . |

| Regulatory and Standards | Ensure the fabric meets relevant industry standards and regulations, such as those related to safety, durability, and environmental impact . |

Installation and Construction Process

The installation of PVC Tensile Fabric structures is a multi-step process that requires careful planning and execution. The process typically involves the following stages:

1 Site Preparation and Setup

Before the installation begins, the site must be prepared and set up. This includes clearing the area, leveling the ground, and setting up the necessary equipment and tools. The site must be prepared to ensure that the structure is stable and safe.

2 Framework and Support Structure Installation

The framework and support structure are installed next. This includes the installation of the main supports, cables, and tensioning systems. The framework must be securely anchored to the ground to ensure the stability of the structure.

3 Fabric Installation and Tensioning

Once the framework is in place, the PVC Tensile Fabric is installed and tensioned. The fabric is carefully placed over the framework and tensioned to the desired level. The tensioning process is critical to ensure that the fabric is taut and properly supported.

4 Final Inspection and Commissioning

After the fabric is installed and tensioned, a final inspection is conducted to ensure that the structure is stable and meets all safety and performance standards. The structure is then commissioned, and any necessary adjustments are made.

| Stage | Description |

| Design and Engineering | The design process begins with a site visit or detailed review of photographs to determine the optimal roof form and structural requirements. Initial conceptual sketches are developed and reviewed with the client for approval. A 3D design package is created to visualize the final structure . |

| Fabrication | The manufacturing process involves the production of custom steel components, membrane panels, and the application of coatings. The membrane is fabricated using advanced techniques such as RF welding to ensure strength and durability. Quality control is essential throughout the fabrication process . |

| Site Preparation | Site preparation includes the installation of anchor bolts, foundation work, and the setup of equipment for installation. Coordination with other trades and the preparation of the site are crucial for a smooth installation process . |

| Installation | The installation process involves the assembly of the structural framework, the placement of the membrane, and the tensioning of the fabric. Specialized equipment such as come-alongs, scissor lifts, and boom lifts may be used. The tensioning process must be carefully controlled to ensure the correct tension and final form of the structure . |

| Quality Control and Final Adjustments | Throughout the installation, quality control measures are implemented to ensure that all components are properly installed and that the structure meets the design specifications. Final adjustments are made to ensure the correct tension and alignment of the fabric . |

| Maintenance and Handover | After installation, the structure is handed over to the client, with documentation and maintenance instructions provided. Ongoing maintenance and support may be offered to ensure the long-term performance of the structure . |

Maintenance and Longevity

PVC Tensile Fabric structures require minimal maintenance, but regular inspections and cleaning are recommended to ensure their longevity. The fabric should be cleaned regularly to remove dirt, debris, and other contaminants that can accumulate on the surface. In some cases, the fabric may need to be re-tensioned or repaired if any damage occurs.

1 Cleaning and Maintenance Procedures

Cleaning the fabric is typically done using mild detergents and water. The fabric should be cleaned according to the manufacturer's recommendations to avoid damage. In some cases, specialized cleaning solutions may be used for more stubborn stains or contaminants.

2 Repair and Replacement

If any damage occurs to the fabric, it can be repaired or replaced. Minor repairs can be done on-site, while more extensive repairs may require the fabric to be sent to a specialized facility for repair or replacement.

3 Longevity and Warranty

PVC Tensile Fabric is designed to last for many years, with some products offering warranties of up to 12 years. The longevity of the fabric depends on factors such as the quality of the materials, the installation process, and the environmental conditions. Proper maintenance and care can help extend the life of the fabric.

| Aspect | Description |

| Regular Cleaning | Regular cleaning is essential to maintain the appearance and performance of the fabric. Using neutral cleaning agents and avoiding harsh chemicals is recommended . |

| Environmental Protection | Protecting the fabric from environmental factors such as UV radiation, moisture, and temperature fluctuations can help extend its lifespan. Anti-UV treatments can enhance resistance to UV damage . |

| Proper Storage and Handling | Proper storage and handling during transportation and installation can prevent damage and ensure the longevity of the fabric. Avoiding exposure to extreme temperatures and physical stress is important . |

| Coating and Topcoats | Applying additional topcoats, such as polyurethane-acrylic or polyvinylidene fluoride coatings, can further enhance the durability and reduce maintenance requirements . |

| Inspection and Maintenance | Regular inspection and maintenance are necessary to identify and address any issues early. This includes checking for signs of wear, tear, or damage . |

| Longevity | The longevity of PVC Tensile Fabric can vary depending on the quality of the material, environmental conditions, and maintenance practices. High-quality PVC Tarpaulin can last for several years, with some heavy-duty applications lasting more than 10 years . |

Environmental and Sustainability Considerations

The production and use of PVC Tensile Fabric are increasingly focused on sustainability. Manufacturers are adopting eco-friendly practices and materials to reduce the environmental impact of their products. This includes the use of recycled materials, energy-efficient production processes, and the development of more sustainable packaging and disposal methods.

1 Eco-Friendly Production Practices

Manufacturers are exploring ways to reduce the environmental impact of PVC Tensile Fabric production. This includes the use of renewable energy sources, the reduction of waste and emissions, and the development of more sustainable manufacturing processes.

2 Sustainable Materials and Practices

The use of sustainable materials and practices is becoming more common in the industry. This includes the use of recycled PVC, the development of biodegradable coatings, and the implementation of closed-loop manufacturing systems.

3 End-of-Life Management

The end-of-life management of PVC Tensile Fabric is an important consideration. The fabric can be recycled or disposed of in an environmentally responsible manner. Some manufacturers are developing programs for the collection and recycling of used fabric, ensuring that it does not end up in landfills.

Challenges and Limitations

Despite its many advantages, PVC Tensile Fabric also faces some challenges and limitations that must be considered when using it in various applications.

1 Cost and Availability

One of the main challenges is the cost of PVC Tensile Fabric. The material can be more expensive than traditional materials such as metal or glass, which may limit its use in budget-constrained projects. Additionally, the availability of the material can be limited in certain regions, making it difficult to source in some areas.

2 Environmental Impact

The production and disposal of PVC Tensile Fabric can have environmental impacts. PVC is a synthetic material that is not biodegradable, and its production involves the use of chemicals and energy. While manufacturers are working to reduce the environmental impact of PVC production, the material's environmental footprint remains a concern.

3 Durability and Maintenance

While PVC Tensile Fabric is durable and resistant to weathering, it can still be affected by environmental factors such as UV radiation, extreme temperatures, and mechanical stress. Over time, the material may degrade, and maintenance may be required to ensure its longevity. Regular cleaning and inspection are necessary to maintain the material's performance.

4 Installation and Expertise

The installation of PVC Tensile Fabric structures requires specialized knowledge and expertise. The process involves careful planning, engineering, and construction, and it is not a DIY project. The need for skilled labor and specialized equipment can be a challenge in some regions.

| Challenge/Limitation | Description |

| Environmental Aging | Long-term exposure to ultraviolet rays, high temperature, and humidity can cause PVC aging and fiber fatigue, reducing tensile strength. High-quality products can mitigate this by adding a UV protective layer . |

| Material Degradation | Over time, materials like PVC can become brittle and lose flexibility due to exposure to high UV levels. This can lead to a significant loss of inherent flexibility . |

| Installation and Maintenance | Improper tensioning angles, connection methods, or local stress concentration can cause early damage, affecting the tensile performance of the fabric . |

| Cost and Repair | PVC can be costly to install and difficult to repair, especially for older structures. Low temperatures may also cause PVC to shatter or experience puncture damage, making it unsuitable for colder climates . |

| Durability and Longevity | While PVC Tensile Fabric is durable, it may not last as long as some high-end materials like PTFE. However, high-quality PVC can still reliably last for 20-25 years . |

| Environmental Impact | While recyclable, the production and disposal of PVC can have environmental impacts, though recycling efforts are increasing . |

| Fire Performance | While PVC contains fire retardants, it may not perform as well as some other materials like PTFE in terms of fire resistance . |

| Design and Standardization | There is a lack of standardized codes for the design of fabric structures, which can make design and engineering more complex . |

Frequently Asked Questions (FAQs) about PVC Tensile Fabric

To help potential buyers and users of PVC Tensile Fabric better understand the material, here are some frequently asked questions (FAQs) along with detailed answers.

Q1: What is PVC Tensile Fabric?

A: PVC Tensile Fabric is a high-performance material made from a base fabric (such as polyester or glass fiber) coated with multiple layers of polyvinyl chloride (PVC). It is known for its strength, durability, flexibility, and resistance to weather and environmental factors.

Q2: What are the main applications of PVC Tensile Fabric?

A: PVC Tensile Fabric is widely used in architectural structures (e.g., domes, awnings, canopies), temporary and event structures, decorative elements, transportation (e.g., vehicle covers), and industrial applications (e.g., awnings, shading structures).

Q3: What are the key advantages of PVC Tensile Fabric?

A: The key advantages include high tensile strength, durability, flexibility, resistance to UV radiation and weathering, and the ability to be customized in terms of color and design.

Q4: How is PVC Tensile Fabric manufactured?

A: The manufacturing process involves preparing a base fabric (e.g., polyester or glass fiber), applying multiple layers of PVC coating, and quality control to ensure the final product meets performance standards.

Q5: What are the common challenges associated with PVC Tensile Fabric?

A: Challenges include the cost of the material, environmental impact (e.g., non-biodegradability), and the need for specialized installation and maintenance.

Q6: How long does PVC Tensile Fabric last?

A: The lifespan of PVC Tensile Fabric can vary depending on usage and environmental conditions, but it is generally durable and can last for many years with proper maintenance.

Q7: Is PVC Tensile Fabric environmentally friendly?

A: While PVC is not biodegradable, manufacturers are focusing on sustainable practices, such as using recycled materials and reducing environmental impact. However, the material's environmental footprint is still a concern.

Q8: Can PVC Tensile Fabric be repaired or replaced?

A: Yes, PVC Tensile Fabric can be repaired or replaced. Minor repairs can be done on-site, while more extensive repairs may require specialized facilities.

Q9: What are the installation requirements for PVC Tensile Fabric?

A: Installation requires specialized knowledge and equipment, including careful planning, engineering, and construction. It is not a DIY project and requires skilled labor.

Q10: What are the future trends in PVC Tensile Fabric?

A: Future trends include the development of advanced materials, smart technologies, sustainable practices, and increased focus on sustainability and innovation.

Case Studies and Real-World Applications

To better understand the practical applications of PVC Tensile Fabric, let's explore some real-world case studies and examples of how this material is used in various industries and projects.

1 Architectural and Structural Projects

PVC Tensile Fabric is widely used in architectural projects that require large, open, and visually striking structures. One notable example is the Guggenheim Museum in Bilbao, Spain, which features a complex, curved roof structure that utilizes tensile fabric to create a dynamic and iconic design. The use of PVC Tensile Fabric in this project allowed for the creation of a lightweight, durable, and visually striking structure that has become a landmark of modern architecture.

Another example is the Water Cube in Beijing, China, which was designed for the 2008 Olympic Games. The structure features a large, transparent roof made of PVC Tensile Fabric, which provides excellent light transmission and weather resistance. The use of this material allowed for the creation of a large, open, and functional space that was both functional and aesthetically pleasing.

2 Temporary and Event Structures

PVC Tensile Fabric is also widely used in the construction of temporary and event structures. These structures are often used for events such as concerts, exhibitions, and trade shows. The material's flexibility and durability make it ideal for temporary applications where quick setup and easy disassembly are required.

One example is the Glastonbury Festival in the UK, where PVC Tensile Fabric is used to create large, temporary structures such as stages, awnings, and shelters. The material's ability to withstand harsh weather conditions and its ease of installation make it a popular choice for such events.

3 Industrial and Commercial Applications

PVC Tensile Fabric is also used in industrial and commercial applications where durability and functionality are key. For example, in the automotive industry, PVC Tensile Fabric is used to create covers for vehicles, such as car covers and truck covers. The material's resistance to UV radiation and weathering makes it ideal for outdoor applications.

In the commercial sector, PVC Tensile Fabric is used for the construction of awnings, canopies, and shading structures. These applications are common in retail environments, where the material provides protection from the elements and enhances the aesthetic appeal of the space.

4 Artistic and Cultural Installations

PVC Tensile Fabric is also used in artistic and cultural installations, where the material's flexibility and visual appeal are leveraged to create unique and engaging experiences. For example, the Cloud Gate sculpture in Chicago, USA, features a large, reflective surface made of glass and steel, but the surrounding structure incorporates elements of tensile fabric to create a dynamic and interactive experience for visitors.

Another example is the Cloud Gate sculpture in London, UK, which features a similar design and uses tensile fabric to create a visually striking and interactive experience for visitors.

5 Environmental and Sustainable Applications

PVC Tensile Fabric is increasingly being used in environmental and sustainable applications. For example, the material is used in the construction of green roofs and sustainable buildings, where it provides insulation, weather resistance, and aesthetic appeal. The use of PVC Tensile Fabric in these applications helps to reduce energy consumption and promote sustainability.

In renewable energy projects, PVC Tensile Fabric is used in the construction of solar panel installations, where the material provides protection and durability for the solar panels. The material's resistance to UV radiation and weathering makes it ideal for outdoor applications.

Future Developments and Innovations

The future of PVC Tensile Fabric is likely to be shaped by ongoing technological advancements and innovations. The development of new materials, manufacturing techniques, and design approaches will continue to enhance the capabilities and applications of PVC Tensile Fabric.

1 Advanced Materials and Coatings

The development of new materials and coatings will enhance the performance and durability of PVC Tensile Fabric. This includes the development of more resistant coatings, improved tensile strength, and enhanced UV resistance. The use of nanotechnology and advanced materials science may lead to the development of new materials that are lighter, stronger, and more durable.

2 Smart and Interactive Structures

The integration of smart technologies into PVC Tensile Fabric structures is a growing trend. This includes the development of interactive and responsive structures that can adapt to changing environmental conditions. For example, smart fabrics that can change color or shape in response to environmental stimuli could be used in architectural and artistic applications.

3 Digital Design and Manufacturing

The use of digital design and manufacturing technologies, such as 3D printing and advanced CAD software, will continue to revolutionize the design and production of PVC Tensile Fabric structures. These technologies will enable more precise and efficient design, faster prototyping, and more complex and innovative structures.

4 Sustainability and Eco-Friendly Practices

The focus on sustainability and eco-friendly practices will continue to influence the development of PVC Tensile Fabric. This includes the use of recycled materials, energy-efficient production processes, and the development of more sustainable packaging and disposal methods. The industry will likely see more emphasis on reducing the environmental impact of PVC production and promoting circular economy principles.

Global Market and Industry Trends

The global market for PVC Tensile Fabric is experiencing steady growth, driven by increasing demand from various industries such as architecture, construction, and event management. The market is characterized by innovation, technological advancements, and a growing focus on sustainability.

1 Market Growth and Expansion

The global market for PVC Tensile Fabric is expanding rapidly, with increasing adoption in both developed and emerging economies. The growth is fueled by the increasing demand for high-performance materials in architectural and construction projects, as well as the rise of temporary and event-based structures.

2 Key Players and Manufacturers

The market is dominated by several key players and manufacturers who are continuously innovating and expanding their product offerings. These companies invest in research and development to improve the quality and performance of their products, while also focusing on sustainable manufacturing practices.

3 Emerging Markets and Opportunities

Emerging markets, particularly in Asia and the Middle East, are presenting significant growth opportunities for PVC Tensile Fabric. The increasing urbanization and infrastructure development in these regions are driving demand for high-performance materials like PVC Tensile Fabric.

4 Investment and Innovation

The industry is witnessing significant investment in innovation, with companies focusing on the development of new materials, coatings, and manufacturing techniques. This includes the use of advanced technologies such as 3D printing and digital design to enhance the design and production of PVC Tensile Fabric structures.

Sustainability and Environmental Impact

The production and use of PVC Tensile Fabric are increasingly being scrutinized for their environmental impact. While the material offers many benefits, there is a growing focus on reducing its environmental footprint through sustainable practices and the development of eco-friendly alternatives.

1 Life Cycle Assessment

Life cycle assessment (LCA) is being used to evaluate the environmental impact of PVC Tensile Fabric from production to disposal. This helps in identifying areas for improvement and promoting more sustainable practices.

2 Recycling and Waste Management

The recycling and waste management of PVC Tensile Fabric is an important consideration. While the material is not easily biodegradable, efforts are being made to develop recycling programs and closed-loop manufacturing systems to reduce waste.

3 Eco-Friendly Alternatives

The development of eco-friendly alternatives, such as biodegradable coatings and recycled materials, is gaining traction. These alternatives aim to reduce the environmental impact of PVC Tensile Fabric while maintaining its performance and durability.

Future Outlook and Predictions

The future of PVC Tensile Fabric is likely to be shaped by ongoing technological advancements, sustainability initiatives, and changing market dynamics. The industry is expected to continue growing, with a focus on innovation, sustainability, and the development of new applications.

1 Technological Advancements

The integration of smart technologies, such as IoT and AI, into PVC Tensile Fabric structures is expected to enhance their functionality and adaptability. This includes the development of interactive and responsive structures that can adapt to changing environmental conditions.

2 Sustainable Practices

The focus on sustainability will continue to drive innovation in the industry. This includes the development of more sustainable manufacturing processes, the use of recycled materials, and the implementation of circular economy principles.

3 Market Expansion

The global market for PVC Tensile Fabric is expected to continue expanding, with increasing adoption in new markets and applications. The growth will be driven by the increasing demand for high-performance materials in architecture, construction, and event management.

English

English Español

Español русский

русский