Content

- 1 Section 1: Introduction to Inflatable Fabric

- 2 Properties of Inflatable Fabric

- 3 Section 2: Applications of Inflatable Fabric

- 4 Section 3: The Manufacturing Process of Inflatable Fabric

- 5

- 6 Section 4: Environmental and Safety Considerations

- 7 Section 5: Customization and Design Options

- 8 Section 6: Maintenance and Care of Inflatable Fabric

- 9 Section 7: Buyer’s Guide to Purchasing Inflatable Fabric Products

- 10 Section 8: Common Challenges and Solutions for Buyers

- 11

- 12 Section 9: Best Practices for Buyers

- 13 Section 10: The Global Market for Inflatable Fabric Products

- 14 Section 11: The Role of Inflatable Fabric in Sustainable Development

- 15 Section 12: The Impact of Inflatable Fabric on Various Industries

- 16

- 17 Section 13: The Role of Inflatable Fabric in Modern Event and Entertainment Industry

- 18 Section 14: The Future of Inflatable Fabric in the Global Economy

- 19

- 20 Section 15: The Role of Inflatable Fabric in Global Supply Chains and Logistics

- 21 Section 16: The Future of Inflatable Fabric Technology

Section 1: Introduction to Inflatable Fabric

Inflatable fabric is a specialized type of material designed to be inflated with air or gas, allowing it to expand and take shape. It is widely used in various applications, including recreational, commercial, and industrial sectors. The material is known for its durability, flexibility, and adaptability to different environments.

Properties of Inflatable Fabric

Inflatable fabric is designed to withstand a variety of environmental conditions while maintaining its integrity and functionality. Some of the key properties of inflatable fabric include:

- Weather Resistance: Inflatable fabric is designed to withstand harsh weather conditions, including rain, high winds, and prolonged sun exposure. This makes it ideal for outdoor installations and events .

- Lightweight and Flexible: Inflatable fabric is lightweight and flexible, making it easy to transport and store. It can be inflated and deflated quickly, making it ideal for temporary structures and events .

- Durability and Tear Resistance: Inflatable fabric is designed to resist tearing and abrasion, ensuring it can withstand challenging environments. It also exhibits high tensile strength, making it suitable for long-term use .

- Flame-Retardant and Waterproof Options: Inflatable fabric can be manufactured with flame-retardant and waterproof options, meeting international safety standards for various applications .

- UV Resistance: Inflatable fabric is treated with UV-resistant coatings to protect it from the damaging effects of prolonged sun exposure .

| Property | Description |

| Weather Resistance | Inflatable fabric is designed to withstand harsh weather conditions, including rain, high winds, and prolonged sun exposure. This makes it ideal for outdoor installations and events . |

| Lightweight and Flexible | Inflatable fabric is lightweight and flexible, making it easy to transport and store. It can be inflated and deflated quickly, making it ideal for temporary structures and events . |

| Tear and Abrasion Resistance | Inflatable fabric exhibits powerful tensile strength properties, which make it resistant to tearing and abrasion, delivering extended durability during challenging surroundings . |

| Flame-Retardant and Waterproof Options | Inflatable fabric can be manufactured with flame-retardant and waterproof options, meeting international safety requirements for dangerous applications . |

| Durability and Longevity | Inflatable fabric is designed to withstand various environmental conditions, including temperature fluctuations, humidity, and exposure to UV radiation. This ensures long-term performance and durability . |

| Customization Options | Inflatable fabric can be customized with various colors, patterns, and branding elements. This allows for personalized and visually appealing structures . |

| Mechanical Properties | Inflatable fabric undergoes mechanical characterization, including tensile strength, abrasion resistance, and fatigue behavior, to ensure its performance in various applications . |

| Environmental Resistance | Inflatable fabric is treated with UV-resistant coatings to protect it from the damaging effects of prolonged sun exposure . |

| Packability and Portability | Inflatable fabric is lightweight and portable, making it easy to transport and set up. This makes it ideal for applications such as camping or outdoor events . |

Section 2: Applications of Inflatable Fabric

Inflatable fabric is used in a wide range of applications across various industries. Some of the most common applications include:

- Outdoor Events and Promotions: Inflatable fabric is widely used for outdoor events, such as marathons, races, and promotional events. Inflatable structures, such as inflatable towers and tents, are popular for attracting attention and enhancing the event experience .

- Aerospace and Space Exploration: Inflatable fabric is used in the development of inflatable habitats and structures for space exploration. These structures are designed to withstand the harsh conditions of space and provide a safe and comfortable environment for astronauts .

- Marine and Nautical Applications: Inflatable fabric is used in the construction of inflatable boats, tenders, and other marine vessels. These vessels are designed to be lightweight, durable, and resistant to water and weather conditions .

- Advertising and Entertainment: Inflatable fabric is used in the creation of inflatable advertising structures, such as inflatable characters and interactive installations. These structures are popular for events, festivals, and promotional activities .

- Construction and Temporary Structures: Inflatable fabric is used in the construction of temporary structures, such as inflatable warehouses, tents, and temporary housing. These structures are ideal for short-term use and can be easily assembled and disassembled .

| Application | Description |

| Outdoor and Event Structures | Inflatable fabric is widely used in outdoor events, such as bounce houses, water slides, and event structures. It is also used in temporary shelters and pavilions for events and festivals . |

| Marine and Nautical Applications | Inflatable fabric is used in marine applications, including inflatable boats, life rafts, and buoyancy systems. It is also used in offshore industries for oil booms and salvage operations . |

| Aerospace and Defense | Inflatable fabric is used in aerospace applications, such as inflatable aerodynamic nose cones for space shuttles and inflatable structures for spacecraft. It is also used in military applications, such as inflatable bridges and floating structures . |

| Medical and Healthcare | Inflatable fabric is used in medical applications, such as inflatable medical devices, blood pressure cuffs, and inflatable mattresses. It is also used in life-saving equipment, such as life rafts and emergency flotation devices . |

| Industrial and Construction | Inflatable fabric is used in industrial applications, such as inflatable seals, pneumatic lifting devices, and temporary shelters. It is also used in construction for temporary enclosures and protective structures . |

| Transportation and Logistics | Inflatable fabric is used in transportation applications, such as truck curtains, cargo covers, and protective linings. It is also used in the production of inflatable bags and bladders for various industries . |

| Safety and Emergency Equipment | Inflatable fabric is used in safety equipment, such as life-saving devices, emergency flotation systems, and safety vests. It is also used in fire safety and emergency response applications . |

| Recreation and Leisure | Inflatable fabric is used in recreational applications, such as inflatable playground equipment, water slides, and amusement park attractions. It is also used in camping and outdoor leisure activities . |

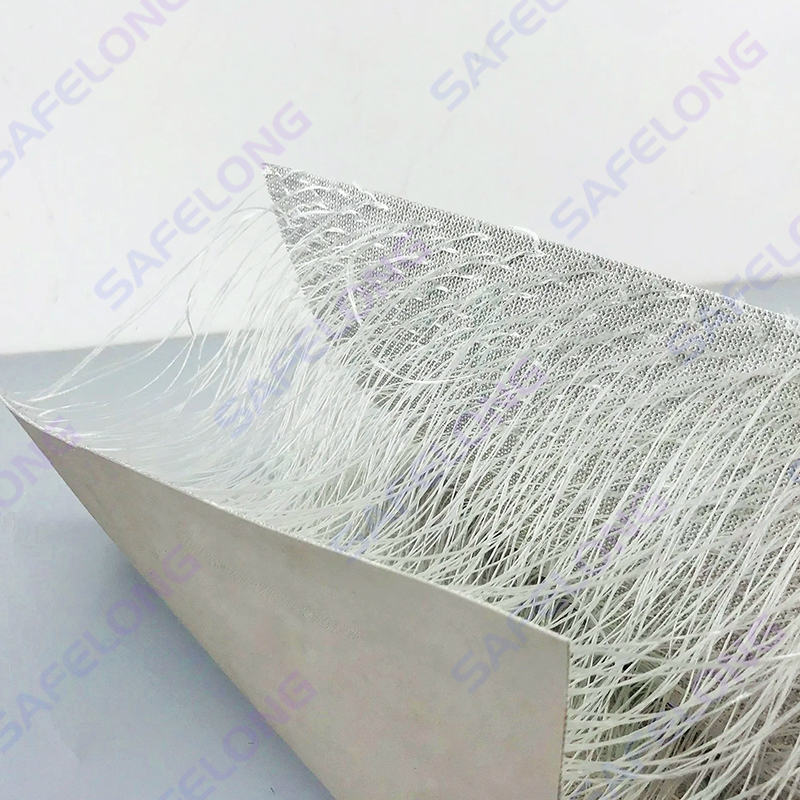

Section 3: The Manufacturing Process of Inflatable Fabric

The production of inflatable fabric involves a series of steps that transform raw materials into a durable, functional product. Understanding the manufacturing process is essential for buyers who want to understand the quality, cost, and reliability of the products they purchase.

Raw Materials

The primary materials used in the production of inflatable fabric include:

- Polyvinyl Chloride (PVC): A common material used in inflatable fabric due to its flexibility, durability, and resistance to weather. PVC is often used in the production of inflatable structures like bounce houses and water slides.

- Neoprene: A synthetic rubber that is highly resistant to UV radiation, chemicals, and extreme temperatures. Neoprene is often used in high-performance inflatable applications.

- Polyethylene (PE): A lightweight and durable material that is often used in the production of inflatable fabrics for outdoor and marine applications.

- Coatings and Sealants: These are applied to the fabric to enhance its durability, waterproofing, and resistance to environmental factors.

Manufacturing Steps

-

- Raw materials are cut and processed into the desired shapes and sizes. This may involve extrusion, calendaring, or embossing to create the base fabric.

-

- The base fabric is coated with protective layers to enhance its durability, waterproofing, and resistance to environmental factors. This may include applying UV-resistant coatings, flame-retardant treatments, or waterproofing agents.

-

- Customization is a key part of the manufacturing process. Inflatable fabric can be printed with logos, images, or branding to meet specific customer requirements. This is often done using digital printing or screen printing techniques.

-

- Each batch of inflatable fabric undergoes rigorous quality control checks to ensure it meets industry standards. This includes testing for durability, waterproofing, and resistance to environmental factors.

-

- Once the inflatable fabric is produced, it is carefully packaged and prepared for shipping. This may include folding, sealing, and labeling to ensure the product arrives in good condition.

| Step | Description |

| Material Preparation | The process begins with the selection of high-quality materials, such as PVC, polyurethane, or other synthetic fabrics. These materials are chosen for their durability, flexibility, and resistance to environmental factors . |

| Cutting and Shaping | The selected fabric is cut into the required shapes and sizes using methods such as laser cutting, mechanical cutting, or water jet cutting. This ensures precision and accuracy in the final product . |

| Surface Preparation | Before assembly, the surfaces of the fabric are cleaned and treated with special compounds to ensure proper adhesion and durability. This may involve the use of organic solvents and drying processes . |

| Assembly and Gluing | The cut pieces are assembled and glued together using specialized adhesives. The gluing process is critical to ensure the structural integrity of the inflatable fabric. Proper surface preparation and alignment are essential to avoid defects such as bubbles or wrinkles . |

| Quality Control | After assembly, the inflatable fabric undergoes quality control checks to ensure it meets safety and performance standards. This includes checking for any defects, ensuring proper sealing, and verifying the integrity of the seams . |

| Final Processing | The final product may undergo additional processing, such as coating or finishing, to enhance its durability and performance. This may include the application of protective coatings or the addition of functional features . |

Section 4: Environmental and Safety Considerations

The use of inflatable fabric in various applications raises important environmental and safety considerations. Buyers should be aware of these factors when selecting products.

Environmental Impact

- Sustainability: The production of inflatable fabric involves the use of synthetic materials, which may have environmental impacts. However, many manufacturers are adopting sustainable practices, such as using recycled materials and reducing waste.

- Disposal: Inflatable fabric products are generally recyclable, but proper disposal is important to minimize environmental impact.

Safety Standards

- Flame Retardancy: Inflatable fabric is often treated with flame-retardant chemicals to meet safety standards and reduce the risk of fire.

- Waterproofing: Waterproofing treatments are applied to inflatable fabric to ensure it remains functional in wet conditions.

- Durability and Longevity: High-quality inflatable fabric is designed to withstand environmental factors, reducing the need for frequent replacement.

Section 5: Customization and Design Options

Inflatable fabric can be customized to meet specific needs and preferences. Buyers can choose from a variety of options to suit their requirements.

- Design and Aesthetics: Inflatable fabric can be customized with various colors, patterns, and branding elements. This allows for personalized and visually appealing structures .

- Size and Shape: Inflatable fabric can be manufactured in various sizes and shapes to meet specific requirements. Customization options include different shapes, sizes, and configurations .

- Environmental Considerations: Inflatable fabric is designed to withstand various environmental conditions, including temperature fluctuations, humidity, and exposure to UV radiation. This ensures long-term performance and durability .

Section 6: Maintenance and Care of Inflatable Fabric

Proper maintenance and care are essential to ensure the longevity and performance of inflatable fabric. Some of the key maintenance tips include:

- Cleaning and Storage: Inflatable fabric should be cleaned regularly to remove dirt and debris. It should be stored in a dry and protected environment to prevent damage from moisture and UV exposure .

- Inflation and Deflation: Inflatable fabric should be inflated and deflated according to the manufacturer's instructions. Over-inflation or under-inflation can lead to damage and reduced performance .

- Regular Inspection: Regular inspection is recommended to identify any signs of wear and tear, such as tears, abrasions, or leaks. Prompt repair or replacement is necessary to prevent further damage .

| Maintenance Aspect | Description |

| Regular Inspection | Inflatable fabric should be inspected regularly for signs of wear, tear, or damage. This includes checking for leaks, abrasions, or structural integrity issues. |

| Cleaning and Cleaning Agents | Inflatable fabric should be cleaned using appropriate cleaning agents to remove dirt, debris, and contaminants. It is important to use mild detergents and avoid harsh chemicals that could damage the fabric. |

| Proper Inflation and Deflation | Inflatable fabric should be inflated and deflated according to the manufacturer's instructions. Over-inflation or under-inflation can lead to damage and reduced performance. |

| Storage Conditions | Inflatable fabric should be stored in a dry and protected environment to prevent damage from moisture, UV exposure, and extreme temperatures. |

| Handling and Transport | Inflatable fabric should be handled with care to avoid sharp edges or rough surfaces that could cause damage. Proper packaging and storage during transport are essential. |

| Regular Maintenance and Servicing | Inflatable fabric should be maintained according to the manufacturer's recommendations. This may include regular inspections, cleaning, and replacement of worn or damaged parts. |

| Repair and Replacement | Damaged or worn-out parts of inflatable fabric should be repaired or replaced promptly to prevent further damage and ensure safety. |

Section 7: Buyer’s Guide to Purchasing Inflatable Fabric Products

For buyers looking to purchase inflatable fabric products, understanding the key factors that influence product quality, cost, and performance is essential. This section provides a comprehensive guide to help buyers make informed decisions when purchasing inflatable fabric products.

Key Considerations for Buyers

-

- Recreational vs. Industrial Use: The intended use of the inflatable fabric product will influence the type of material, durability, and features required. For example, recreational products like bounce houses may require more vibrant colors and interactive features, while industrial applications may prioritize durability and weather resistance.

- Environmental Conditions: Consider the environment in which the product will be used. Products used in harsh weather conditions may require enhanced waterproofing, UV resistance, or flame retardancy.

-

- Material Selection: The choice of material (e.g., PVC, neoprene, polyethylene) will affect the product’s durability, flexibility, and longevity. Higher-quality materials may be more expensive but offer better performance and longevity.

- Coatings and Treatments: Look for products with protective coatings that enhance durability, waterproofing, and resistance to environmental factors.

-

- Customization Options: Buyers may want to customize products with logos, branding, or specific designs. Ensure the manufacturer offers customization services and the quality of the printing or design is high.

- Reinforcement and Edges: Reinforced edges and corners can enhance durability and prevent tearing, especially in high-traffic or high-stress applications.

-

- Quality Standards: Look for products that meet industry standards and certifications, such as flame retardancy, waterproofing, and safety standards.

- Quality Control Processes: Inquire about the manufacturer’s quality control processes to ensure consistent quality and reliability.

-

- Cost Factors: The cost of inflatable fabric products can vary based on material, size, customization, and manufacturing complexity. Buyers should consider the total cost of ownership, including shipping, installation, and maintenance.

- Value for Money: Compare prices from different suppliers and consider the long-term value of the product, including durability and performance.

-

- Supplier Reputation: Research the reputation of the supplier or manufacturer. Look for reviews, testimonials, and industry recognition.

- Customer Support: Ensure the supplier offers good customer service, including technical support, warranty, and after-sales service.

-

- Packaging and Shipping: Consider how the product is packaged and shipped. Proper packaging ensures the product arrives in good condition.

- Delivery Time: Factor in delivery time and shipping costs when making purchasing decisions.

| Consideration | Description |

| Material Quality | Inflatable fabric products are typically made from high-quality materials such as PVC, Oxford fabric, or nylon. These materials are chosen for their durability, flexibility, and resistance to wear and tear . |

| Vendor Reputation | Research the vendor's reputation and track record. Look for vendors with a proven history of delivering high-quality products and adhering to safety standards . |

| Product Range | Consider the variety of products offered by the vendor. A diverse selection ensures that you can find the right product for your specific needs . |

| Safety and Durability | Ensure the product meets safety standards and is designed to withstand environmental conditions. Look for products with warranties and guarantees . |

| Customization Options | Some vendors offer customization options, such as size, color, and design, to meet specific requirements . |

| Pricing and Payment Terms | Consider the pricing structure and payment terms offered by the vendor. Ensure that the terms are clear and transparent . |

| Delivery and Shipping | Inquire about delivery times and shipping options. Consider the cost and time involved in receiving the product . |

| Customer Support | Look for vendors that provide excellent customer support and are responsive to inquiries and concerns . |

Section 8: Common Challenges and Solutions for Buyers

Buyers may encounter various challenges when purchasing inflatable fabric products. Understanding these challenges and their solutions can help buyers avoid common pitfalls and ensure a smooth purchasing experience.

Common Challenges

-

- Challenge: Inflatable fabric products may degrade over time due to environmental factors, UV exposure, or wear and tear.

- Solution: Choose products with high-quality materials, protective coatings, and warranties. Regular maintenance and proper storage can extend the product’s lifespan.

-

- Challenge: Customization options may be limited or the quality of custom designs may not meet expectations.

- Solution: Work closely with the manufacturer to ensure clear communication and review samples before finalizing the order.

-

- Challenge: Shipping delays, damaged products, or improper installation can lead to dissatisfaction.

- Solution: Choose suppliers with reliable shipping and installation services. Ensure proper handling and storage of the product.

-

- Challenge: High costs or budget constraints may limit the choice of products or features.

- Solution: Prioritize essential features and consider cost-effective alternatives. Compare prices and value from different suppliers.

-

- Challenge: Environmental impact and safety concerns may arise from the use of synthetic materials or lack of safety features.

- Solution: Choose products with eco-friendly materials and safety certifications. Follow manufacturer guidelines for safe use and disposal.

Section 9: Best Practices for Buyers

To ensure a successful purchasing experience, buyers should follow best practices that promote informed decision-making and satisfaction.

Best Practices

-

- Research Suppliers: Thoroughly research suppliers and manufacturers, including their reputation, product quality, and customer reviews.

- Compare Options: Compare different products, prices, and features to find the best value for money.

-

- Communicate Needs: Clearly communicate your requirements, including size, customization, and delivery expectations.

- Follow Up: Follow up with the supplier to ensure all requirements are met and to address any issues promptly.

-

- Inspect Products: Inspect products upon receipt to ensure they meet quality standards and are free from defects.

- Test Functionality: Test the product’s functionality and performance before use.

-

- Keep Records: Keep records of purchase details, warranty information, and maintenance logs.

- Maintain Documentation: Maintain documentation for warranty claims, repairs, and future reference.

-

- Feedback and Reviews: Provide feedback to suppliers and share experiences to help improve products and services.

- Stay Informed: Stay informed about industry trends, new products, and best practices.

Section 10: The Global Market for Inflatable Fabric Products

The global market for inflatable fabric products is a dynamic and rapidly growing industry, driven by increasing demand from various sectors. Understanding the global market trends, key players, and future prospects can help buyers and industry stakeholders make informed decisions.

Market Overview

The inflatable fabric market is characterized by a wide range of products, from recreational inflatables to industrial applications. The market is driven by factors such as technological advancements, increasing consumer spending, and the growing popularity of events and entertainment.

Key Market Drivers

-

- The popularity of events, parties, and entertainment venues has led to increased demand for inflatable products such as bounce houses, water slides, and interactive inflatables.

- The rise of home entertainment and outdoor activities has further fueled the demand for inflatable products.

-

- The use of inflatable fabric in industrial applications, such as temporary shelters, advertising, and transportation, has expanded the market.

- The growth of the construction and infrastructure industries has also contributed to the demand for inflatable products.

-

- Advances in materials science and manufacturing techniques have led to the development of more durable, lightweight, and customizable inflatable products.

- The integration of smart technologies and IoT (Internet of Things) is expected to drive innovation in the market.

-

- Economic growth in emerging markets has led to increased disposable income and consumer spending, driving the demand for inflatable products.

- Urbanization has led to the development of new markets and opportunities for inflatable products.

Key Market Trends

-

- The use of eco-friendly and sustainable materials is becoming increasingly important in the inflatable fabric market.

- Consumers and businesses are increasingly aware of environmental issues, leading to a demand for sustainable and recyclable products.

-

- The demand for customized and personalized inflatable products is growing, driven by the rise of branding and marketing needs.

- Customization options, such as printing, branding, and design, are becoming more accessible and popular.

-

- The rise of e-commerce platforms has made it easier for consumers to purchase inflatable products online.

- Digital marketing and online platforms are playing a significant role in the growth of the market.

-

- Increasing regulatory requirements and safety standards are driving the development of higher-quality and safer inflatable products.

- Compliance with international standards is becoming more important for manufacturers and suppliers.

Key Players in the Market

The global inflatable fabric market is dominated by several key players, including:

- Major Manufacturers: Companies such as Inflatables Direct, Party City, Bounce House Masters, and Inflatable World are among the leading manufacturers and suppliers of inflatable products.

- Specialized Suppliers: Companies specializing in specific applications, such as Inflatable Boats, Airbag Manufacturers, and Event Equipment Suppliers.

- Emerging Players: New and innovative companies are entering the market, offering innovative products and services.

Market Challenges and Opportunities

-

- Competition: The market is highly competitive, with many players competing for market share.

- Cost and Pricing: High production costs and pricing can be a challenge for smaller players.

- Environmental Concerns: Environmental regulations and sustainability concerns may impact the market.

-

- Emerging Markets: Growing markets in developing countries offer significant growth opportunities.

- Innovation and Technology: Advances in technology and materials science can drive innovation and new product development.

- Sustainability and Eco-Friendly Products: The demand for sustainable and eco-friendly products presents a significant opportunity.

Section 11: The Role of Inflatable Fabric in Sustainable Development

Inflatable fabric is increasingly being recognized for its role in sustainable development, particularly in the context of environmental protection, resource efficiency, and social responsibility. As the world faces growing challenges related to climate change, waste management, and resource depletion, the use of inflatable fabric offers several advantages that align with sustainable development goals.

Environmental Benefits of Inflatable Fabric

-

- Inflatable fabric is often made from lightweight and recyclable materials, which reduces the consumption of raw materials and energy during production.

- The lightweight nature of inflatable fabric makes it easier to transport and store, reducing the carbon footprint associated with logistics.

-

- Many inflatable fabric products are designed to be reusable and recyclable, reducing the amount of waste generated.

- The ability to reuse inflatable products in various applications extends their lifespan and reduces the need for new production.

-

- Inflatable fabric products are often energy-efficient, especially when used in applications such as temporary shelters or event structures, where they can be easily set up and dismantled.

- The use of inflatable fabric in energy-efficient designs can contribute to reducing overall energy consumption.

-

- The development of eco-friendly and biodegradable materials for inflatable fabric is an emerging trend, offering more sustainable alternatives to traditional synthetic materials.

- The use of recycled materials in the production of inflatable fabric is becoming more common, further enhancing their sustainability.

Social and Economic Benefits

-

- Inflatable fabric products are often more cost-effective compared to traditional alternatives, especially in applications where temporary or short-term solutions are needed.

- The reusability of inflatable products reduces the need for repeated investments, making them a cost-effective solution for various applications.

-

- Inflatable fabric products are often more accessible and inclusive, especially in developing regions where resources are limited.

- The affordability and portability of inflatable products make them suitable for a wide range of users, including those in underserved communities.

-

- Inflatable fabric products are widely used in community events, festivals, and public spaces, enhancing social interaction and community engagement.

- The use of inflatable fabric in public spaces can contribute to the development of vibrant and inclusive communities.

Challenges and Opportunities

-

- Despite the benefits, the production and disposal of inflatable fabric products can still have environmental impacts, such as the use of synthetic materials and the generation of waste.

- Addressing these challenges requires ongoing innovation in materials science and waste management practices.

-

- The development of regulatory frameworks and policies that support the use of sustainable materials and practices is essential for the long-term sustainability of inflatable fabric.

- Collaboration between industry stakeholders, governments, and consumers is crucial for promoting sustainable practices.

-

- Raising awareness about the environmental and social benefits of inflatable fabric can encourage more sustainable consumption patterns.

- Education and outreach efforts can help consumers make informed choices and support the adoption of sustainable practices.

Section 12: The Impact of Inflatable Fabric on Various Industries

Inflatable fabric has transcended its traditional use in recreational and entertainment applications to become a versatile material with significant impacts across a wide range of industries. Its unique properties—such as flexibility, durability, portability, and adaptability—make it suitable for applications in sectors ranging from construction and healthcare to aerospace and emergency response.

1. Construction and Infrastructure

Inflatable fabric is increasingly used in the construction and infrastructure sectors for temporary and semi-permanent structures.

- Temporary Shelters and Housing: Inflatable fabric is used to create temporary shelters for disaster relief, refugee camps, and emergency housing. These structures are lightweight, easy to deploy, and can be quickly assembled and disassembled.

- Construction Sites: Inflatable fabric is used to create temporary fencing, barriers, and enclosures on construction sites, improving safety and site management.

- Event Structures: Inflatable fabric is used to create temporary structures for events, such as stages, seating, and canopies, providing flexible and cost-effective solutions.

2. Healthcare and Medical Applications

Inflatable fabric has found applications in the healthcare sector, particularly in the development of medical devices and equipment.

- Portable Medical Equipment: Inflatable fabric is used in the production of portable medical devices, such as inflatable beds, stretchers, and medical tents, which are used in field hospitals and emergency medical services.

- Wound Care and Therapy: Inflatable fabric is used in the development of therapeutic devices, such as inflatable splints and supports, which aid in the treatment of injuries and medical conditions.

- Sanitation and Hygiene: Inflatable fabric is used in the production of portable toilets and sanitation facilities, improving hygiene and comfort in field operations.

3. Transportation and Logistics

Inflatable fabric is widely used in the transportation and logistics industry for various applications.

- Inflatable Boats and Rafts: Inflatable fabric is used in the production of inflatable boats, rafts, and other watercraft, which are lightweight, portable, and easy to transport.

- Aircraft and Aerospace: Inflatable fabric is used in the production of inflatable components for aircraft, such as airbags, emergency escape systems, and inflatable structures for space exploration.

- Logistics and Supply Chain: Inflatable fabric is used in the production of packaging and storage solutions, such as inflatable containers and packaging materials, which are lightweight and easy to transport.

4. Agriculture and Farming

Inflatable fabric is used in agriculture for various applications, including:

- Greenhouses and Greenhouses: Inflatable fabric is used in the construction of temporary greenhouses and agricultural structures, providing a cost-effective and flexible solution for crop production.

- Animal Husbandry: Inflatable fabric is used in the production of animal shelters, feed storage, and animal enclosures, improving animal welfare and farm efficiency.

- Irrigation and Water Management: Inflatable fabric is used in the production of irrigation systems and water management solutions, such as inflatable dams and water storage.

5. Emergency Response and Disaster Relief

Inflatable fabric plays a critical role in emergency response and disaster relief operations.

- Emergency Shelters: Inflatable fabric is used to create temporary shelters for displaced populations, providing immediate and effective solutions in disaster-affected areas.

- Medical and Sanitation Facilities: Inflatable fabric is used in the production of medical tents, sanitation facilities, and hygiene stations, improving the delivery of essential services in emergency situations.

- Logistics and Supply Chain: Inflatable fabric is used in the production of emergency supply containers and logistics equipment, ensuring the efficient delivery of aid and resources.

6. Retail and Consumer Goods

Inflatable fabric is increasingly used in retail and consumer goods for various applications.

- Recreational Products: Inflatable fabric is used in the production of recreational products, such as bounce houses, water slides, and interactive inflatables, which are popular for events and entertainment.

- Branded and Promotional Products: Inflatable fabric is used in the production of branded and promotional products, such as inflatable displays, advertising structures, and promotional items.

- Consumer Goods: Inflatable fabric is used in the production of consumer goods, such as inflatable furniture, storage solutions, and portable products.

7. Environmental and Sustainability Applications

Inflatable fabric is increasingly used in environmental and sustainability applications.

- Environmental Protection: Inflatable fabric is used in the production of environmental protection equipment, such as inflatable barriers and containment systems, which help prevent pollution and protect natural resources.

- Sustainable Materials: The use of eco-friendly and sustainable materials in inflatable fabric production is increasing, reducing the environmental impact of these products.

- Recycling and Reuse: Inflatable fabric is designed to be reusable and recyclable, reducing waste and promoting sustainable practices.

Section 13: The Role of Inflatable Fabric in Modern Event and Entertainment Industry

The modern event and entertainment industry has seen a significant transformation, with inflatable fabric playing a pivotal role in creating immersive, engaging, and memorable experiences for audiences. From large-scale festivals to intimate gatherings, inflatable fabric products are increasingly being used to enhance the visual appeal, interactivity, and overall experience of events.

1. Enhancing Event Atmosphere and Engagement

Inflatable fabric is widely used to create vibrant and dynamic environments that captivate audiences.

- Visual Appeal: Inflatable structures such as bounce houses, water slides, and interactive inflatables are popular at events, providing a fun and engaging experience for attendees. These structures are often brightly colored and designed to attract attention and encourage participation.

- Interactive Elements: Many inflatable products incorporate interactive features, such as games, puzzles, and activities, which enhance engagement and create memorable experiences. For example, interactive inflatables can include obstacle courses, photo booths, and interactive games that encourage social interaction.

- Customization and Branding: Inflatable fabric can be customized with logos, branding, and designs, making it an effective tool for event promotion and branding. Customized inflatable structures can be used to create branded zones, promotional displays, and interactive experiences that align with event themes.

2. Flexibility and Portability

One of the key advantages of inflatable fabric is its flexibility and portability, which makes it ideal for a wide range of event settings.

- Ease of Setup and Teardown: Inflatable fabric products are lightweight and easy to transport, making them ideal for events that require quick setup and teardown. This is particularly useful for outdoor events, festivals, and temporary installations.

- Space Efficiency: Inflatable structures can be deflated and stored in compact sizes, making them ideal for limited space environments. This allows for efficient use of space and reduces the need for large storage areas.

- Adaptability: Inflatable fabric can be easily adapted to different shapes and sizes, allowing for customization to fit specific event requirements. This flexibility makes it suitable for a wide range of event types, from small intimate gatherings to large-scale festivals.

3. Cost-Effectiveness and Versatility

Inflatable fabric offers a cost-effective solution for event organizers, offering a balance between quality and affordability.

- Cost-Effectiveness: Inflatable fabric products are generally more cost-effective compared to traditional event structures, especially for short-term or temporary events. The reusability of inflatable products also reduces the need for repeated investments, making them a cost-effective solution for repeated use.

- Versatility: Inflatable fabric can be used in a variety of applications, from entertainment to commercial and industrial uses. This versatility makes it a valuable asset for event organizers who need to adapt to different event types and requirements.

4. Safety and Durability

The safety and durability of inflatable fabric products are important considerations for event organizers.

- Safety Standards: Inflatable fabric products are often designed to meet safety standards, including flame retardancy, waterproofing, and structural integrity. This ensures that the products are safe for use in various environments.

- Durability: High-quality inflatable fabric is designed to withstand environmental factors, such as UV exposure, weather, and wear and tear. This ensures that the products remain functional and safe throughout their use.

5. Environmental and Sustainability Considerations

The use of inflatable fabric in the event industry also raises environmental and sustainability considerations.

- Sustainability: The use of eco-friendly and sustainable materials in inflatable fabric production is increasing, reducing the environmental impact of these products. The use of recycled materials and biodegradable materials is becoming more common, contributing to sustainable practices.

- Recycling and Reuse: Inflatable fabric products are designed to be reusable and recyclable, reducing waste and promoting sustainable practices. This aligns with the growing emphasis on sustainability in the event industry.

Section 14: The Future of Inflatable Fabric in the Global Economy

The global economy is increasingly influenced by technological advancements, sustainability trends, and consumer preferences. Inflatable fabric, as a versatile and adaptable material, is well-positioned to play a significant role in shaping the future of various industries. This section explores the potential impact of inflatable fabric on the global economy, focusing on emerging trends, market dynamics, and long-term implications.

1. Economic Growth and Market Expansion

The global economy is experiencing steady growth, driven by increasing consumer spending, urbanization, and technological innovation. Inflatable fabric, as a product of innovation, is poised to benefit from these trends.

- Market Expansion: The global market for inflatable fabric is expected to grow significantly, driven by increasing demand from various sectors such as recreation, construction, healthcare, and transportation. The versatility of inflatable fabric allows it to be used in a wide range of applications, making it a valuable asset for businesses and consumers alike.

- Economic Diversification: Inflatable fabric can contribute to economic diversification by providing cost-effective solutions for various industries. For example, in the construction and infrastructure sectors, inflatable fabric offers a flexible and cost-effective alternative to traditional materials, reducing costs and improving efficiency.

2. Technological Advancements and Innovation

Technological advancements are driving innovation in the field of inflatable fabric, leading to new applications and opportunities.

- Smart Materials and Digital Integration: The development of smart materials and digital integration is transforming the way inflatable fabric is used. For example, the integration of IoT (Internet of Things) technology into inflatable structures allows for remote monitoring, control, and data collection, enhancing the functionality and efficiency of inflatable products.

- Advanced Manufacturing Processes: Advances in manufacturing processes, such as 3D printing and automation, are improving the production efficiency and quality of inflatable fabric. These advancements are reducing production costs and enabling the production of more complex and customized products.

3. Sustainability and Environmental Impact

Sustainability is a key concern in the global economy, and inflatable fabric is increasingly being recognized for its potential to contribute to sustainable development.

- Eco-Friendly Materials: The use of eco-friendly and sustainable materials in the production of inflatable fabric is becoming more prevalent. This includes the use of recycled materials, biodegradable materials, and sustainable manufacturing practices.

- Reduced Environmental Impact: Inflatable fabric is designed to be reusable and recyclable, reducing the environmental impact of these products. This aligns with the growing emphasis on sustainability in the global economy.

4. Global Trade and Supply Chain

The global trade landscape is evolving, with increasing interconnectedness and supply chain complexities. Inflatable fabric is well-positioned to benefit from these trends.

- Global Trade Opportunities: The global market for inflatable fabric offers opportunities for international trade and collaboration. The versatility of inflatable fabric makes it a valuable product for global markets, with applications in various industries.

- Supply Chain Efficiency: The portability and lightweight nature of inflatable fabric make it ideal for global transportation and logistics. This allows for efficient and cost-effective distribution of inflatable products across global markets.

5. Consumer Behavior and Market Trends

Consumer behavior is increasingly influenced by sustainability, innovation, and personalization. Inflatable fabric is well-positioned to meet these evolving consumer preferences.

- Personalization and Customization: The ability to customize inflatable fabric products to meet specific needs and preferences is a growing trend. This includes personalized branding, design, and functionality, which enhances the consumer experience.

- Sustainability and Ethical Consumption: Consumers are increasingly aware of environmental and ethical issues, leading to a demand for sustainable and ethically produced products. Inflatable fabric, with its potential for sustainability, is well-positioned to meet these consumer demands.

6. Challenges and Opportunities

Despite the potential for growth and innovation, the global economy faces challenges that could impact the development of inflatable fabric.

- Regulatory and Ethical Concerns: The use of new technologies and materials in inflatable fabric may raise ethical and regulatory concerns. Addressing these concerns through collaboration and innovation is essential for sustainable development.

- Competition and Market Dynamics: The competitive nature of the global market requires continuous innovation and adaptation to maintain a competitive edge. Companies that invest in research and development and embrace innovation are likely to thrive in this dynamic market.

Section 15: The Role of Inflatable Fabric in Global Supply Chains and Logistics

In the modern global economy, supply chains and logistics play a critical role in the movement of goods and services. Inflatable fabric, as a lightweight, portable, and versatile material, is increasingly being utilized in various aspects of global supply chains and logistics, offering unique advantages and opportunities.

1. Portability and Flexibility in Logistics

One of the most significant advantages of inflatable fabric is its portability and flexibility, which makes it ideal for logistics and transportation.

- Lightweight and Compact: Inflatable fabric products are lightweight and can be deflated and compacted for easy transportation. This reduces the space required for storage and transportation, making it ideal for air and sea freight.

- Adaptability: Inflatable fabric can be easily adapted to different shapes and sizes, allowing for customization to fit specific logistical needs. This flexibility is particularly useful in the transportation of goods that require temporary or semi-permanent structures.

2. Applications in Transportation and Storage

Inflatable fabric is widely used in various transportation and storage applications, enhancing efficiency and reducing costs.

- Transportation of Goods: Inflatable fabric is used in the production of packaging materials, such as inflatable containers and packaging solutions, which are lightweight and easy to transport. This reduces the cost and complexity of transporting goods.

- Storage Solutions: Inflatable fabric is used in the production of storage solutions, such as inflatable storage bags and containers, which are ideal for temporary storage of goods in various industries.

3. Emergency and Disaster Response

Inflatable fabric plays a critical role in emergency and disaster response logistics, providing essential infrastructure and support.

- Emergency Shelters: Inflatable fabric is used in the production of emergency shelters and temporary housing, providing immediate and effective solutions in disaster-affected areas.

- Logistics and Supply Chain: Inflatable fabric is used in the production of emergency supply containers and logistics equipment, ensuring the efficient delivery of aid and resources in emergency situations.

4. Environmental and Sustainability Considerations

The use of inflatable fabric in global supply chains and logistics also raises environmental and sustainability considerations.

- Sustainability: The use of eco-friendly and sustainable materials in inflatable fabric production is increasing, reducing the environmental impact of these products. The use of recycled materials and biodegradable materials is becoming more common, contributing to sustainable practices.

- Recycling and Reuse: Inflatable fabric products are designed to be reusable and recyclable, reducing waste and promoting sustainable practices. This aligns with the growing emphasis on sustainability in the global economy.

5. Challenges and Opportunities

Despite the potential for growth and innovation, the global supply chain and logistics industry faces challenges that could impact the development of inflatable fabric.

- Regulatory and Ethical Concerns: The use of new technologies and materials in inflatable fabric may raise ethical and regulatory concerns. Addressing these concerns through collaboration and innovation is essential for sustainable development.

- Competition and Market Dynamics: The competitive nature of the global market requires continuous innovation and adaptation to maintain a competitive edge. Companies that invest in research and development and embrace innovation are likely to thrive in this dynamic market.

Section 16: The Future of Inflatable Fabric Technology

The future of inflatable fabric technology is poised for significant advancements, driven by innovations in materials science, manufacturing processes, and digital integration. These developments will likely enhance the performance, durability, and versatility of inflatable fabric products, opening up new applications and opportunities across various industries.

Advancements in Materials Science

-

- The development of smart materials that can respond to environmental changes (e.g., temperature, humidity, or mechanical stress) will enable inflatable fabric to adapt to different conditions. For example, materials that can self-heal minor tears or adjust their properties based on external stimuli.

- The integration of phase-change materials (PCMs) could allow inflatable fabric to regulate temperature, making it suitable for extreme environments.

-

- Research into biodegradable and sustainable materials will continue to reduce the environmental impact of inflatable fabric. Materials derived from renewable resources, such as bio-based polymers and natural fibers, will become more prevalent.

- The use of recycled materials in the production of inflatable fabric will also increase, contributing to circular economy principles.

-

- New coating technologies will enhance the durability, waterproofing, and UV resistance of inflatable fabric. Self-cleaning and anti-microbial coatings may also be developed to improve maintenance and hygiene.

Digital Integration and IoT

-

- The integration of IoT (Internet of Things) technology into inflatable fabric will enable remote monitoring, control, and data collection. For example, sensors embedded in inflatable structures can monitor pressure, temperature, and structural integrity, providing real-time data for maintenance and safety.

- Smart inflatables could be used in applications such as smart cities, where they can serve as energy-efficient and adaptive infrastructure.

-

- Advances in 3D printing and additive manufacturing will allow for the production of complex and customized inflatable structures with greater precision and efficiency. This will enable rapid prototyping and on-demand manufacturing.

- Digital design tools and simulation software will improve the design and testing of inflatable fabric products, reducing development time and costs.

Enhanced Manufacturing Processes

-

- The adoption of automation and robotics in manufacturing will improve production efficiency, reduce labor costs, and enhance quality control. Automated systems can perform tasks such as cutting, sewing, and assembly with high precision.

- AI-driven quality control systems will ensure consistent product quality and reduce defects.

-

- The implementation of sustainable manufacturing practices, such as energy-efficient production processes and waste reduction, will become more widespread. This will align with global sustainability goals and regulatory requirements.

New Applications and Industries

-

- The development of new industries and applications will be driven by the capabilities of advanced inflatable fabric. For example, inflatable structures could be used in space exploration, underwater habitats, or disaster relief efforts.

- The use of inflatable fabric in medical and healthcare applications, such as temporary medical tents or portable medical devices, could also expand.

-

- The ability to customize inflatable fabric products at a high level of detail will become more accessible. Digital design tools and 3D printing will enable mass customization, allowing for personalized products tailored to specific needs and preferences.

Challenges and Opportunities

-

- The development and implementation of advanced technologies require significant investment in research and development. Companies that invest in innovation will likely gain a competitive advantage.

- Collaboration between industry stakeholders, academia, and government agencies will be essential to drive innovation and share resources.

-

- The use of new technologies and materials will raise ethical and regulatory questions. Ensuring the safety, privacy, and ethical use of inflatable fabric products will be important.

- International standards and regulations will need to be developed to address the unique challenges posed by new technologies.

English

English Español

Español русский

русский