In the construction and engineering sectors, PVC Tensile Fabric has attracted significant attention for its unique properties and wide range of applications. As one of Jiangsu Sulong Eco-Technologies Co., Ltd.'s core products, this material not only embodies technological innovation but also holds stringent international certifications, such as ISO quality, environmental, and occupational health system certifications, as well as national safety standards MA and KA certifications and the EU CE certification, ensuring superior quality and reliability.

What is the basic definition of PVC Tensile Fabric?

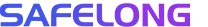

PVC Tensile Fabric is a high-strength synthetic fabric based on a polyvinyl chloride (PVC) coating, designed to withstand high tensile loads. It is formed through a specialized weaving process and coating to form a flexible membrane that maintains structural stability and functionality under various environmental conditions. Jiangsu Sulong Eco-Technologies Co., Ltd., through its certification system, ensures that this material adheres to strict environmental and safety standards during its manufacturing process, thereby enhancing its competitiveness in the global market.

What are the core characteristics of PVC Tensile Fabric?

This material exhibits excellent durability and aging resistance, resisting UV rays, extreme temperatures, and chemical corrosion, ensuring structural integrity over long-term use. Its waterproof and fire-resistant properties are achieved through a specialized coating, effectively reducing maintenance requirements and enhancing safety levels. Jiangsu Sulong Eco-Technologies Co., Ltd.'s products also feature high airtightness and low permeability, thanks to the company's MA and KA certifications. This ensures effective control of air flow and pressure loss in industrial applications.

Where is PVC Tensile Fabric widely used?

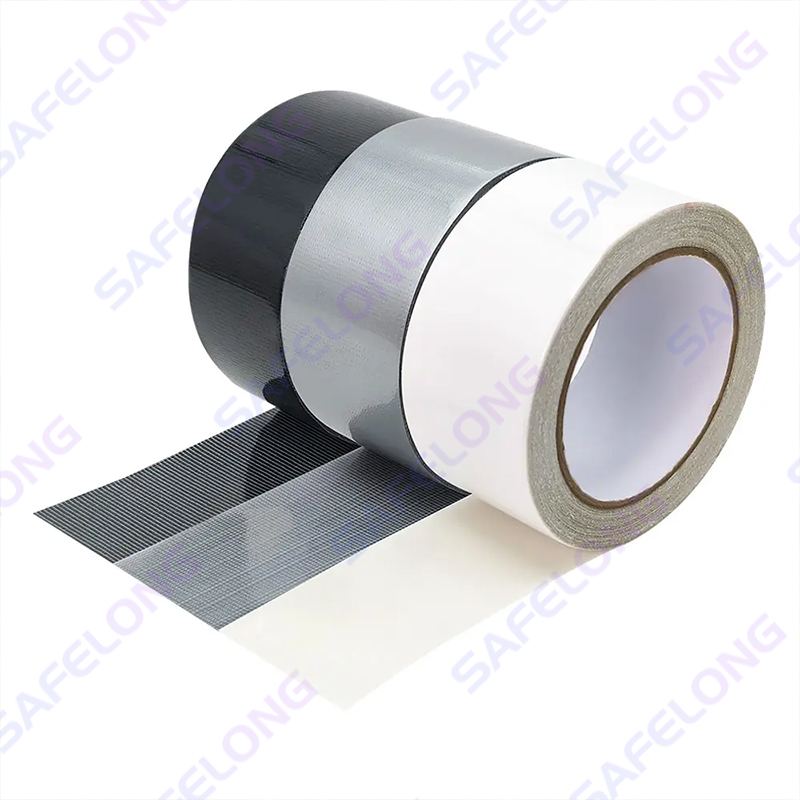

This material is widely used in large-scale building structures, such as stadium roof coverings, exhibition center awnings, and transportation hub shelters, providing lightweight yet durable covering solutions. In environmental engineering projects, it is used in airtight duct systems to support industrial ventilation and pollution control projects. Jiangsu Sulong Eco-Technologies Co., Ltd.'s CE-certified products have further expanded its international market, including sustainable building projects in Europe, demonstrating the material's versatility and adaptability.

How is PVC Tensile Fabric environmentally friendly?

With a recyclable PVC base material and a low-VOC (volatile organic compound) coating, PVC Tensile Fabric reduces its environmental impact and supports the principles of a circular economy. Jiangsu Sulong Eco-Technologies Co., Ltd.'s environmental management system certification highlights its energy-saving and emission-reduction measures in production, ensuring efficient resource utilization and minimal waste throughout the material's lifecycle. This environmental focus makes the material an ideal choice for green building and sustainability initiatives.

Why is quality control crucial for PVC Tensile Fabric?

Strict quality control is the cornerstone of ensuring material performance and safety, encompassing comprehensive monitoring from raw material sourcing to finished product testing. Jiangsu Sulong Eco-Technologies Co., Ltd.'s ISO-certified system covers quality, environmental, and occupational health management. MA, KA, and CE certifications verify the product's airtightness and structural reliability. These certifications not only ensure user safety but also enhance the material's suitability for high-pressure environments (such as industrial duct systems), reducing the risk of failure and extending its service life.

What are the advantages of choosing PVC Tensile Fabric?

This material offers a cost-effective solution, reducing installation costs and shortening project cycles through lightweight design while maintaining high load capacity and aesthetic flexibility. Jiangsu Sulong Eco-Technologies Co., Ltd.'s professional certifications, such as CE certification, ensure compliance with international safety regulations, making it a reliable partner for global projects. Furthermore, the material's customizability allows designers to adjust color, light transmittance, and shape to specific needs, driving innovative applications.

What is Jiangsu Sulong Eco-Technologies Co., Ltd.'s role in the PVC Tensile Fabric sector?

As an industry leader, the company integrates international certifications into its R&D and production processes, ensuring that its PVC Tensile Fabric meets the highest standards for airtight fabrics and ducting. Its MA and KA certifications highlight national safety compliance, while CE certification supports product exports and global collaboration. With ISO system certification, Jiangsu Sulong Eco-Technologies Co., Ltd. not only enhances the performance consistency of its materials but also promotes the advancement of environmental protection technologies, providing the market with reliable solutions.

英语

英语 西班牙语

西班牙语 俄语

俄语