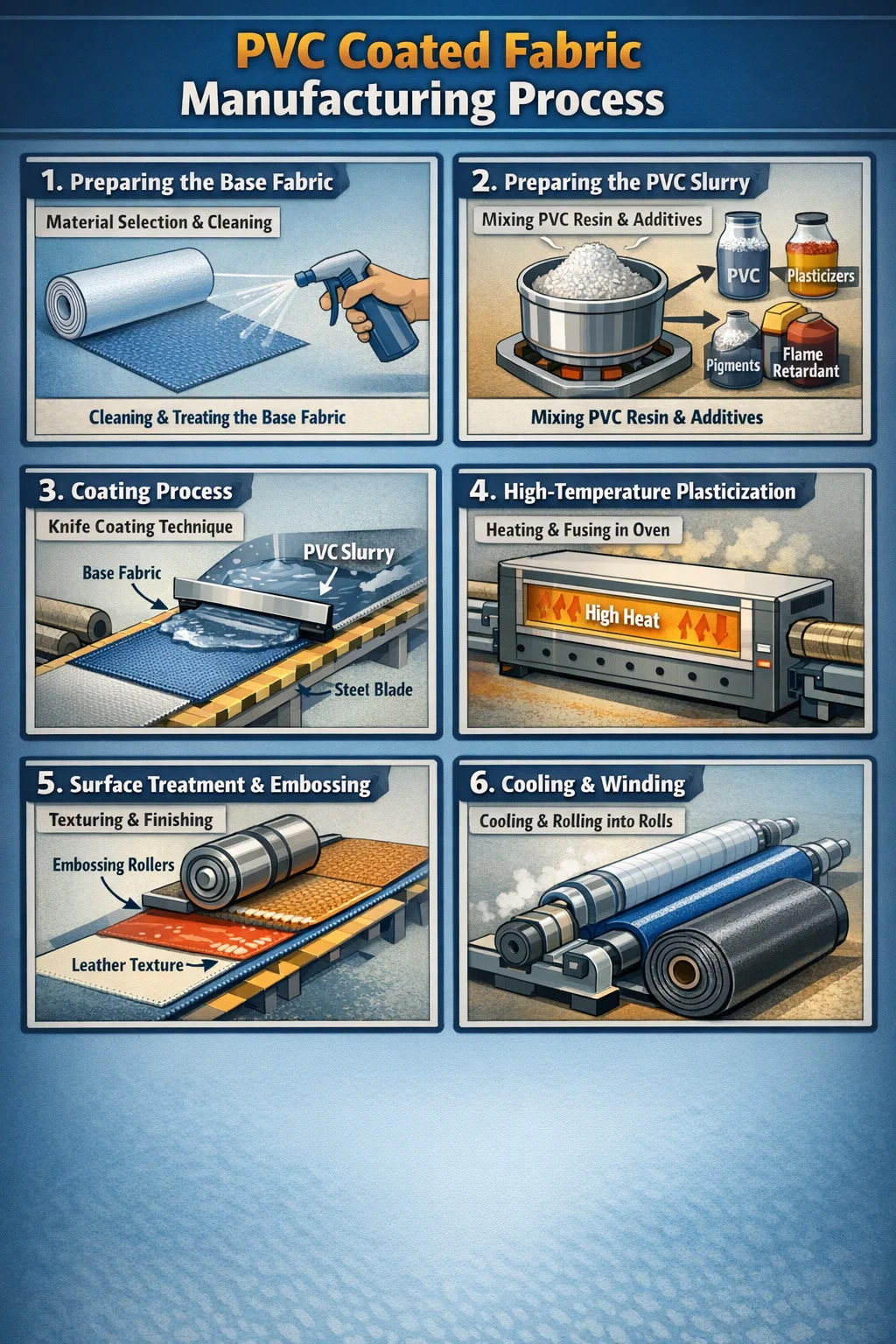

The process of making PVC coated fabric is somewhat like giving a piece of cloth a "plastic armor." Simply put, it involves evenly applying liquid PVC material onto a base fabric and then using high temperature to fuse them together.

Content

- 1 Here are the main steps in making this material:

- 1.1 1. Preparing the base fabric (selecting the "skeleton")

- 1.2 2. Preparing the PVC slurry (preparing the "paint")

- 1.3 3. Coating process (applying the "paint" to the fabric)

- 1.4 4. High-temperature plasticization (baking and shaping)

- 1.5 5. Surface Treatment and Embossing (Surface Modification)

- 1.6 6. Cooling and Winding

Here are the main steps in making this material:

1. Preparing the base fabric (selecting the "skeleton")

First, the base fabric must be selected, which acts as the "skeleton" of the fabric.

Material selection: Manufacturers usually choose different fabrics depending on the final application; the most commonly used is strong polyester fiber.

Cleaning and treatment: The base fabric must be cleaned and flattened before coating to ensure that the surface is free of impurities. Sometimes a very thin layer of "adhesive" is applied beforehand to help the subsequent PVC coating adhere more firmly.

2. Preparing the PVC slurry (preparing the "paint")

PVC is a powder at room temperature, so it needs to be transformed into a flowable slurry.

Mixing the formula: The PVC resin powder is mixed with a liquid called a plasticizer to make it into a paste-like consistency.

Adding additives: Depending on the requirements, colors (pigments), sunscreens (UV protection), or fire-retardant materials are added to give the fabric different colors and functions.

3. Coating process (applying the "paint" to the fabric)

This is the most crucial step, and the most common method is called "knife coating."

Knife coating: The fabric moves at a constant speed like a conveyor belt, with a precise steel blade above it. The slurry is poured onto the fabric surface, and the steel blade, like spreading butter, evenly presses the slurry into the gaps of the fabric.

Thickness control: By adjusting the distance between the steel blade and the fabric, the thickness of this "armor" can be precisely controlled.

4. High-temperature plasticization (baking and shaping)

The newly applied slurry is still soft and needs to pass through a long oven.

Heating and fusion: Under high-temperature heating, the various components in the slurry will completely fuse, transforming from a liquid to a solid.

Tight bonding: This step allows the PVC coating to tightly "grip" the fibers of the base fabric, preventing it from peeling off after cooling.

5. Surface Treatment and Embossing (Surface Modification)

Although the fabric is already formed after baking, it may undergo further processing to improve its appearance and functionality.

Embossing: While the material is still warm, it is passed through patterned rollers to create textures resembling leather or anti-slip patterns.

Protective Coating: Sometimes, a thin, transparent protective film is sprayed on the surface to make it less prone to dust accumulation and easier to clean.

6. Cooling and Winding

Finally, the fabric is cooled down by cooling rollers and neatly wound into large rolls by a machine, becoming the finished PVC-coated fabric product that we see.

English

English Español

Español русский

русский